- Description

- Application

- Specification

- Warranty

- Measure

SeceuroDoor 77 Fast - High Speed Insulated Steel Roller Shutter

When is a "high speed door" actually the right solution for you? In reality, it depends entirely on your specific application. We find that many customers searching for high speed doors don't necessarily need a complex fabric rapid-roll system—they simply need a door that is significantly faster than the slow, outdated shutter they currently have.

The SeceuroDoor 77 Fast bridges this gap perfectly. It is an electrically operated, double-skinned steel roller shutter that utilises a powerful, high-rated industrial motor with adjustable speed settings. It delivers the speed you need without sacrificing the security of a solid steel door.

Secure Speed vs. Fabric Doors

Traditionally, a "high speed door" in the UK referred to a lightweight fabric curtain designed purely for climate control in very busy environments. While excellent for rapid access, these fabric doors offer zero security and almost always require a secondary heavy-duty door to secure the building overnight.

The SeceuroDoor 77 Fast solves this two-door problem. It is a robust, double-skinned steel shutter that provides:

- Solid Security: A physical steel barrier that protects your premises.

- Thermal Insulation: Foam-filled slats to retain heat and reduce energy costs.

- Rapid Operation: Fitted with a high-speed GfA motor drive.

Performance & Efficiency

Standard basic roller shutters can take over a minute to fully open, which frustrates staff and lets heat escape. In contrast, a SeceuroDoor 77 Fast at 5000mm high can open in less than 20 seconds (potentially as fast as 11 seconds depending on settings). This dramatic reduction in waiting time improves workflow efficiency and minimises thermal loss.

Note: Not just any door can be made "fast." The shutter curtain must be of a specific strength and construction to withstand the forces of a high-speed motor. The SeceuroDoor 77 uses a specially engineered double-skin profile designed to handle these stresses without tearing or warping.

Customisation & Control

Every door is made to measure as standard to ensure a perfect fit for your opening. You can choose from a wide range of standard Polyester Powder Coated (PPC) colours, with special bespoke colours available on request to match your branding.

Automation Options

Because it is a high-speed door, many customers prefer automated operation for seamless traffic flow. We offer various intelligent control options:

- Radar Detection: The most popular choice for reliable, hands-free operation. The door detects approaching traffic (forklifts or vehicles) and opens automatically.

- Standard Controls: Simple wall-mounted control panels or handheld remote controls are also available for manual operation.

Any building where there is high levels of traffic or a need to keep the door closed as much as possible. However we also find many customers just also appreciate a roller door which opens faster, regardless of application. Time is money and so on....

As a double skinned steel roller door this door is also great for almost any building where some insulation and a quieter door curtain in the high winds is appreciated.

High-Performance Construction

The SeceuroDoor 77 Fast insulated roller shutter combines the robust durability of our proven SeceuroDoor 75 model with the dual benefits of thermal insulation and high-speed operation. It is the ideal solution for businesses requiring security, energy efficiency, and rapid access in a single package.

Every door is made to measure to the millimetre, ensuring a precise fit for your specific opening.

Intelligent GfA Motor & Diagnostics

At the heart of this door is a high-powered GfA direct drive motor. GfA drive systems are renowned for their smooth, powerful reliability and leading-edge control technology.

Smart Management with GfA-Stick

Modern industrial doors require modern diagnostics. By registering your new door with GfA and utilising their Bluetooth dongle diagnostic tool (the GfA-Stick), you benefit from an industry-leading 2-year warranty.

The GfA-Stick, coupled with the GfA+ mobile App, provides complete transparency regarding your door's performance:

- Real-Time Data: Plug in the Stick to download a complete operational history.

- Diagnostic Readout: View current settings, programming parameters, and a log of the last 6 faults.

- Event Logging: Access a record of the last 128 events, including cycle counts and motor temperature.

- Easy Troubleshooting: This data makes it simple to pinpoint whether an issue lies with the control panel, motor, installation, or user operation, minimising downtime.

Thermal & Acoustic Insulation

The door features a sophisticated design to minimise thermal bridging. The slats are filled with fine-pored PU rigid foam, which ensures effective thermal insulation. Additionally, the comprehensive curtain and sealing technology around the entire shutter perimeter significantly reduces noise transfer from both inside and outside the building.

Technical Specifications

- Slat Profile: 77mm insulated steel slat

- Thermal Performance: Heat transmission coefficient of 4.01 W/(m²K) for the single slat profile

- Maximum Width: 6000 mm

- Maximum Area: 20 m²

- Guide Rails: Standard guide angle is 75mm x 50mm (Choice of 4 guide arrangements; other sizes available on request)

Customisation Options

- Motor Supply: Available with your choice of Three-Phase (415V) or Single-Phase (240V) motor drives to suit your site power supply.

- Finish: Can be powder coated in almost any RAL colour to match your facility's aesthetics.

SeceuroDoor Product Warranty

All SeceuroDoor products, including the industrial motor, are guaranteed against defects of material or workmanship by SWS UK, subject to correct installation, maintenance and operation, for a period of 1 year from the date of purchase. This comprehensive warranty provides peace of mind and protection for your investment in premium industrial door solutions.

Extended Warranty for GfA Motors

An exclusive extended 2-year warranty is available on GfA industrial motors when you register each drive using the GfA bluetooth dongle. Registration is straightforward and provides additional benefits including viewing and tracking all registered GfA assets in one place, monitoring ongoing usage patterns, keeping track of drive settings over time, accessing a comprehensive library of fault codes, and synching your service records.

Warranty Coverage

SWS UK will replace or repair any components of our products where the manufacturing process has resulted in a defect occurring during the relevant warranty period, subject to the exceptions and conditions detailed below. For all replacement electrical parts, the warranty period is 12 months or the remainder of the original warranty period, whichever is the longest.

Warranty Limitations and Exclusions

The SeceuroDoor warranty does not cover the following circumstances:

Visual Quality Standards

- Marks, distortion, stains, blemishes, indentations or scuffs which are not observable from at least 3 metres away in natural light (not direct sunlight)

- Minor variations in finish associated with the manufacturing process

- Impact damage or scratches, dents, scuffs or other minor abrasions occurring post-installation

Installation and Maintenance Issues

- Incorrect installation of the product, not following SWS UK's installation instructions

- Incorrect operation of the product or lack of proper care and maintenance in accordance with SWS UK's Operating & Maintenance Manual

- Any modifications made to the product by anyone other than SWS UK

- Use or attempted use of non-SWS UK spare parts

- Repairs or attempted repairs undertaken by any person other than someone specifically authorised by SWS UK

- Any attempt to reduce operating clearances by means of infills or draughtproofing

Normal Wear and Environmental Factors

- Normal wear and tear from regular usage

- Accidental or malicious damage from third parties

- External influences such as extreme or abnormal weather conditions, fire, water, salts, chemicals and bird droppings

- Any fault or surge in the customer's electricity supply

- Any failure of masonry or other structures onto which the product has been fixed

Coastal and High-Corrosion Environments

- Rust or corrosion caused by exposure to saltwater or salty air for products installed within 500 metres of the sea or a large body of saltwater

- For products installed within 2 miles of the sea, the exterior finish of the product is guaranteed for a limited period of 2 years only (regular weekly cleaning with warm water and mild detergent is essential)

Consumables and Consequential Costs

- Consumable items such as fuses, light bulbs or batteries

- Indirect, special or consequential loss or damage howsoever caused, including remedial work costs, call-out fees, tool or plant hire and transport costs

Important Warranty Conditions

The SeceuroDoor warranty covers parts only and does not cover labour costs or consequential costs. This includes but is not limited to call-out fees, transport costs and costs for remedial work for removing and/or re-installing faulty parts. All warranty claims must be reported promptly to allow for timely assessment and resolution.

Product Care Requirements

To maintain warranty validity and prolong the life of your SeceuroDoor product, correct operation and care in accordance with the official Operating & Maintenance Manual is essential. Regular maintenance includes wiping with a damp cloth and mild detergent to remove excessive dirt and grime, ensuring the floor is kept smooth, level and clear of dirt and debris which can damage the rubber seal, and conducting visual inspections to identify any issues before they develop into major problems.

Coastal Installation Requirements

Products installed in coastal environments or high-corrosion areas require enhanced maintenance protocols. Regular cleaning of products in locations within 2 miles of the sea is especially important. Doors should be cleaned thoroughly weekly using warm water and mild detergent with a soft cloth or sponge, allowed to dry naturally. Never use strong detergent, abrasive, caustic or solvent-based cleaners as these will void the warranty.

Visual Quality Assessment Standards

We recommend performing a visual quality check on installation. Carry out the quality check in natural daylight, not direct sunlight. Stand at a distance of 3 metres from the product to view the overall appearance. The product is acceptable if, taking into account the manufacturing process, none of the following is readily visible on the face of the product: marks or distortions associated with the manufacturing process, minor indentations, marks or scuffs on the surface, or paint or stain blemishes.

Making a Warranty Claim

For warranty claims or technical support, please contact Samson Doors on 01933 448 850 or email enquiries@samsondoors.co.uk. Please have your order details, installation date, and a clear description of the issue available. Our technical team will assess the claim and arrange appropriate resolution in accordance with the warranty terms.

Protecting Your Investment

Regular professional servicing and maintenance by qualified engineers will help ensure optimal performance and longevity of your SeceuroDoor product. Samson Doors offers comprehensive maintenance contracts and emergency repair services across the UK to keep your industrial doors operating reliably year after year.

Measuring, Pricing & Ordering

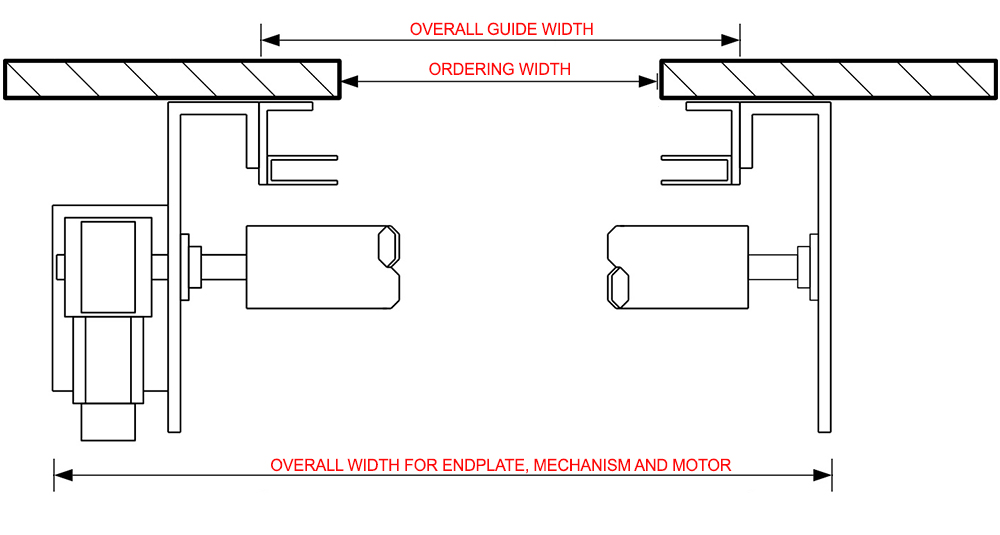

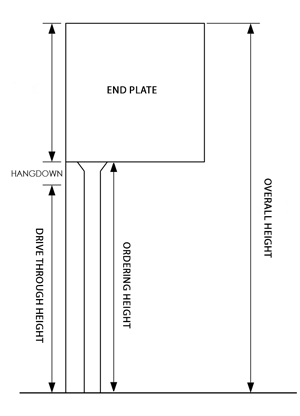

For all electric roller shutter doors with industrial motor drives, we use specific dimensions for pricing and manufacturing. Please refer to the measuring diagram below for visual guidance.

Important Rule: These measurement principles apply regardless of whether the door uses a single-phase or three-phase electric motor system.

Definitions for Ordering

- OPENING WIDTH (between guides) = The Ordering Width

- GUIDE HEIGHT (excluding end plates) = The Ordering Height

Understanding Overall Dimensions

Please be aware that the total physical width of the installed shutter will be greater than your Ordering Width. This "Overall Width" includes the guides and the end plates at high level.

The total width at the top (end plate level) is determined by your motor configuration:

- Outboard Motors: The motor is mounted externally to the end plate. This side will require more side room than the non-motor side.

- Inboard Motors: The motor is mounted within the barrel/tube, reducing side room requirements.

- Drive Type: The choice between chain drive and direct drive motors will also affect the specific width required for the motor assembly.

Manual Override Access

The emergency manual override facility is included as standard. It is located on the same side as the motor (internally) and is accessed directly underneath the end plate. If this position is not suitable for your site, alternative positions are available on request.

End Plate & Curtain Roll Sizes

The size of the end plate is variable. It depends on the specific door model and the total height of the door, as taller doors require a larger curtain roll when fully open. Always check the required headroom for your specific door height.

Installation Configurations

Our "Traditional" build roller shutter doors use steel guides and angle profiles which can be specified to suit different structural openings.

Face Fit - Behind the Opening (Recommended)

This is the standard and recommended installation method for traditional industrial doors.

- The door is installed to the inside face of the wall.

- Ordering Width: In a perfect scenario, this matches your daylight opening width (the guides sit behind the reveals).

- Ordering Height: This matches your floor-to-lintel height (the end plates sit behind the lintel).

- Drive-Through Height Note: All roller shutters have some "hangdown" of the bottom slat when fully open. This means your final clear drive-through height will be slightly less than your Ordering Height. If your clear drive-through height is critical, please contact us to determine the exact height to order.

Reveal Fit - Between the Opening

In some cases, doors must be installed within the opening itself (between the reveals).

- Suitability: This configuration is best suited for electric tube motor roller doors, where components are typically contained within the barrel bounds.

- Industrial Doors: While you can install any roller shutter between an opening, industrial motor-driven models often require additional steelwork or specific adaptation to fit between reveals correctly.

- Ordering Dimensions: When fitting between reveals, your Ordering Width is the total width between the walls, and the guides will reduce the clear drive-through width.

(showing outboard direct drive motor arrangement)