The Hörmann ALR 67 Thermo Glazing is an industrial sectional door designed for buildings where light and visibility are essential, but heat loss is not an option. Unlike standard glazed doors which can be weak points in a building's thermal envelope, this model uses a substantial 67mm deep profile with a genuine thermal break, delivering energy efficiency comparable to many solid panel doors.

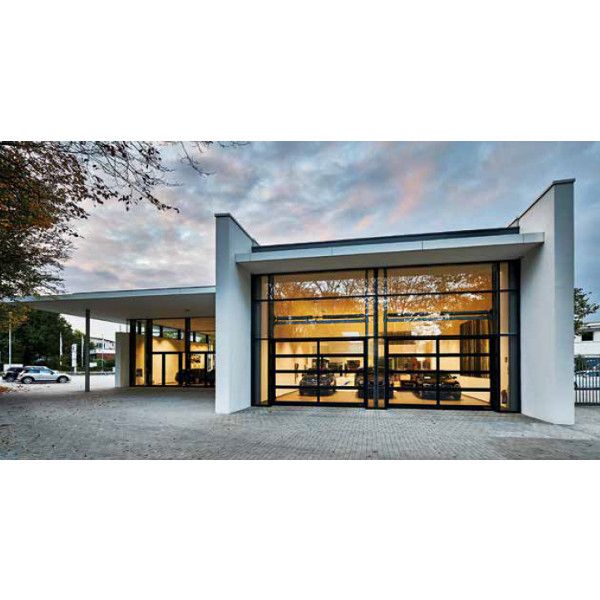

This makes it the ideal specification for modern heated workshops, car showrooms, and commercial units that need to meet stricter Part L building regulations without sacrificing glass area. By separating the inner and outer shells of the aluminium profile, the thermal break prevents cold bridging, significantly reducing the risk of condensation forming on the inside of the frame—a common issue with standard industrial glazing.

Key Specifications

- Profile Depth: 67mm with thermal break

- Max Width: 5500mm

- Max Height: 4000mm

Thermal Performance Data

Performance is calculated according to EN 13241-1 (Appendix B EN 12428) based on a door size of 5000mm x 5000mm. Lower U-values indicate better insulation.

| Glazing Configuration | Standard U-Value (W/m²·K) | With ThermoFrame Upgrade (W/m²·K) |

|---|---|---|

| Standard Double Pane (Single-pane safety glass) |

3.0 | 2.9 |

| Climatic Double Pane (Enhanced insulation glass) |

1.8 | 1.7 |

Note: The optional ThermoFrame adds an additional thermal break between the frame and brickwork, improving system insulation by up to 15%.

- Description

- Application

- Specification

Hörmann ALR 67 Thermo: Maximum Light with Serious Insulation

Premium Glazing with Enhanced Thermal Performance

The Hörmann ALR 67 Thermo bridges the gap between a fully glazed showroom door and a high-performance insulated door. By using a 67 mm deep aluminium profile with an integrated thermal break, it offers U-values as low as 1.6 W/(m²·K) (depending on size and glazing), solving the traditional problem where choosing a glass door meant accepting high heat loss.

This increased depth—25 mm deeper than the standard 42 mm profile—provides significantly better insulation while keeping the visual appeal of a modern, light-filled entrance. It is the ideal specification for heated workshops, logistics hubs, and car showrooms where you need visibility without the energy bills of a standard single-glazed door.

Advanced Thermal Break Construction

The core innovation here is the thermal break. In standard aluminium doors, the metal frame acts as a bridge, conducting cold from the outside to the inside. The ALR 67 Thermo uses a physical barrier within the aluminium profile to separate the inner and outer shells, effectively stopping this heat transfer.

This design also extends to the glazing beads, which are thermally broken to prevent cold spots around the glass edges—typically the weakest point for condensation in industrial doors.

ThermoFrame Option for Maximum Efficiency

For buildings with strict energy targets, the optional ThermoFrame system can improve insulation even further. This additional seal creates a thermal break between the door frame and the brickwork/masonry, reducing energy loss through the side guides and lintel connection. In climate-controlled facilities, this small detail contributes to measurable operational cost savings.

Massive Opening Capabilities

Despite its focus on insulation, this is a heavy-duty industrial door capable of spanning large openings. It can be manufactured up to 10,000 mm wide and 7,500 mm high.

The robust 67 mm profile provides the structural rigidity needed for these spans, allowing even large distribution centres or hangars to benefit from natural light without compromising on door strength or stability.

Glazing Specifications

You can tailor the glass to suit your building’s needs. Standard double-pane glazing offers solid all-round performance, while optional triple-pane units are available for facilities requiring maximum heat retention. The use of real scratch-resistant glass (Duratec) ensures clarity and durability over time, avoiding the clouding often seen with cheaper plastic windows.

Why Natural Light Matters

Installing a fully glazed door isn't just about aesthetics; it’s about the working environment. Substantial natural light reduces reliance on artificial strip lighting and creates a better workspace for staff. With the ALR 67 Thermo, you don’t have to trade this staff wellbeing for thermal efficiency—you get both.

Typical Applications

- Vehicle Showrooms: High visibility for stock while keeping heating costs down.

- Food & Pharmaceutical: Clean, bright environments with stable internal temperatures.

- Logistics Centres: Reducing lighting costs in loading bays.

- Workshops & Manufacturing: Improved staff conditions with controlled ventilation and heat retention.

Weather and Corrosion Resistance

The door is rated for Class 3 wind load resistance, making it stable even in exposed locations. Comprehensive seals between sections and around the glazing provide Class 3 watertightness, keeping rain out effectively. The standard anodised E6/C0 finish offers excellent natural corrosion resistance, making it a durable choice for coastal or aggressive industrial environments.

Operation and Safety

Due to the weight of the glazing and the robust profile, electric operation is the standard recommendation for this model. Industrial-grade operators ensure smooth, safe movement, with soft-start and soft-stop features protecting the glass from unnecessary vibration.

Safety is built-in as standard, including finger-trap protection between sections, side trap guards, and spring break devices to prevent the door dropping in the unlikely event of a failure.

Key Specification Summary

- Section Depth: 67 mm aluminium with thermal break

- Max Width: 10,000 mm

- Max Height: 7,500 mm

- Thermal Insulation: Up to 1.6 W/(m²·K) (size/glazing dependent)

- Glazing: Double or triple-pane options available

- Wind Load: Class 3 resistance

- Finish: Standard Anodised E6/C0 (natural silver) or RAL powder coat

- Best For: Heated buildings requiring maximum daylight

The ALR 67 Thermo is designed for buildings where the "closed" position is just as important as the "open" one. In the UK, where lighting conditions can be poor and heating costs are high, this door creates a moving glass wall that maximises daylight without letting the heat escape.

1. Prestige Car Dealerships & Showrooms

For high-end automotive retailers (such as Audi, Mercedes-Benz, or JLR franchises), the showroom door is the primary frame for the stock. Standard single-glazed industrial doors often suffer from condensation in UK winters, obstructing the view of the vehicles inside. The ALR 67 Thermo’s thermal break technology eliminates this fogging, ensuring your fleet looks pristine from the roadside, even on the coldest mornings.

2. MOT Centres and Vehicle Workshops

Modern service centres are moving away from dark, draughty industrial units. Mechanics working on complex diagnostics need excellent natural light and a comfortable ambient temperature. Installing ALR 67 Thermo doors reduces the reliance on artificial high-bay lighting and maintains a "shirtsleeve" working temperature, which significantly improves staff retention and productivity during the winter months.

3. Garden Centres and Retail Nurseries

Many UK garden centres now utilise large industrial openings to connect indoor retail areas with outdoor plant canopies. The ALR 67 Thermo is the perfect solution here; it allows maximum UV transmission for plant health when closed, but provides a robust thermal barrier that protects sensitive stock (and customers in the café area) from sudden temperature drops.

4. Fire Stations and Emergency Services

With public sector buildings under increasing pressure to meet sustainability targets and reduce carbon footprints, the ALR 67 Thermo is a frequent choice for modern fire stations. It offers the rapid opening speeds required for emergency response, whilst the high insulation values help the building achieve BREEAM excellence ratings by sealing the large appliance bays against heat loss.

5. High-Precision Manufacturing (F1 & Aerospace)

The UK is a global hub for motorsport and aerospace engineering. These facilities require clinically clean, temperature-controlled environments that still need large access routes for fuselages or transporters. The triple-pane glazing options and tight air-permeability seals of this door make it suitable for clean-room adjacent areas where dust ingress and temperature fluctuation must be minimised.

| Technical Specification: ALR 67 Thermo | |

|---|---|

| Construction Features | |

| Profile Depth | 67 mm |

| Thermal Break | ● (Standard) |

| Material | Aluminium |

| Maximum Dimensions | |

| Max Width | 10,000 mm |

| Max Height | 7,500 mm |

| Thermal Insulation (U-Value) 1) | |

| Standard (Double Pane) | 2.2 W/(m²·K) |

| With ThermoFrame | 2.1 W/(m²·K) |

| Optional Climatic Double Pane | 1.7 W/(m²·K) |

| Optional Quadruple Glazing | 1.9 W/(m²·K) |

| Weather Resistance | |

| Water Tightness (EN 12425) | Class 3 (70 Pa) |

| Air Permeability (EN 12426) | Class 2 2) |

| Acoustic Insulation (dB) | 23 dB (Standard) |

Notes:

- 1) U-values based on a door size of 5000 × 5000 mm. Lower values indicate better insulation.

- 2) Class 2 = 12 m³/m²h

- ● Standard finish is Anodised Aluminium E6 / C0. RAL colours available as option.