DescriptionRobust Secur-Dor 2.1 Security Door

The Robust Secur-Dor 2.1 is a made-to-order steel security doorset designed for low to medium risk properties, including residential and social housing developments.

Tested to STS 201 and PAS 24 (2022) and approved by Secured by Design, it is engineered to resist forced entry attempts using hand tools, levers and physical force.

Key benefits

- Third-party tested security performance (STS 201 and PAS 24 (2022)) with Secured by Design approval.

- Fully assembled delivery with hardware pre-fitted as standard for a faster, simpler installation process.

- Single-fix design with adjustable fixing feet and a variable sub-frame to help reduce on-site labour time.

- Durable steel construction suited to high-traffic areas, offering lower maintenance and improved whole-life cost versus timber alternatives.

Hardware options

Secur-Dor 2.1 can be specified with exclusive ARRONE panic hardware developed with HOPPE (UK), tested on PAS 24 (2022) certified doors and designed to deliver a more cost-effective solution than many alternatives.

- Single doors: 2-point bolt panic hardware option.

- Double doors: 1-point bolt on the active leaf and 2-point bolt on the passive leaf for BS EN1125 compliance.

- Non-panic option: high security sashlock (with lever handles) plus double europrofile cylinder and TS007 security escutcheons.

Thermal, fire and durability

- Achieves a U-value of 1.5 W/(m²K) to support Part L Building Regulations compliance.

- Available fire rated on request.

- Optional vision panels or louvres can be specified where required.

- Manufactured in Magnelis® steel with up to a 10-year anti-corrosion warranty as standard.

For projects that require enhanced protection beyond this specification, Robust also offers alternative certified security solutions, including the TUFF-DOR range.

ApplicationThe Robust Secur-Dor 2.1 is designed for environments that require verified security without compromising on aesthetics or functionality. Its PAS 24 accreditation and Secured by Design status make it the preferred choice for projects where safety and crime prevention are critical planning factors.

Social Housing and Residential Developments

As a PAS 24 accredited doorset, the Secur-Dor 2.1 meets the rigorous standards often required by social housing specifications and new-build residential projects. It is ideal for:

- Communal entrance doors for flats and apartments.

- Rear access and balcony doors for individual dwellings.

- Bin stores and cycle storage rooms requiring secure access.

- Social housing refurbishment programs where upgraded security is mandatory.

Commercial and Retail Premises

For businesses, the Secur-Dor 2.1 offers a robust physical barrier against opportunistic burglary while maintaining a professional appearance. Common applications include:

- Staff entrances and rear fire exits in retail outlets.

- Secure office entry points and internal IT server room protection.

- Back-of-house security for shopping centres and leisure facilities.

Public Sector and Community Buildings

Public buildings often face high traffic and the risk of vandalism. The steel construction of the Secur-Dor 2.1 provides superior durability compared to timber or PVC-U alternatives.

- School and university perimeter doors.

- Community centres and sports pavilions.

- Healthcare facilities and clinic rear entrances.

Industrial and Utility

While offering high security, the doorset is also built to withstand harsh environments, making it suitable for:

- Personnel access doors in warehouses and factories.

- Utility substations and plant rooms.

- Remote sites requiring low-maintenance, weather-resistant security.

SpecificationDoor Leaf

- Single Doors Latched (single swing):

- Max width Frame: 1360mm | Leaf: 1285mm

- Max height Frame: 2445mm | Leaf: 2407mm

- Double Doors (single swing - equal or unequally split):

- Max width Frame: 2650mm | Leaf: 1285mm (each leaf)

- Max height Frame: 2445mm | Leaf: 2407mm

- Door Panel Thickness: 55mm

- Material: 1.2mm corrosion resistant Magnelis®.

- Door Leaf Infill: Mineral wool and integral steel stiffeners.

- Door Panel Construction: Two 1.2mm sheets mechanically fixed together, by bonding two steel skins to the rigid core.

Door Sub Frame

- Material: Folded from 1.5mm Magnelis® to match leaf material.

- Frame Extensions: Frame extensions supplied as standard to accommodate site tolerance of -0mm/+30mm. The extensions provide additional protection to the fixings against jemmys.

- Hinges: Specially modified EN1935 Class 13 stainless steel hinges with four security dog bolts.

- Frame Infill: Mineral wool.

- Frame Profile: C frame.

- Threshold: 15mm rebated version as standard meeting the requirements of BS8300 or approved Doc M.

Other Door Options

- Vision Panels: Max width 254mm | Max height 1524mm | Max area 0.38m²

- Louvres: Max width 457mm | Max height 1524mm | Max area 0.69m²

Locking & Hardware

- Manual locking: Yes

- Emergency escape: Yes

Additional Performance

- Fire rating available: Yes (subject to configuration)

- Lower U value available: Yes (subject to configuration)

- Certification: PAS 24 | STS 201 | Secured by Design | BS EN 6375 Yes

InstallationInstallation Guide: Robust Steel Doorsets

Robust steel doorsets are engineered with one clear goal: to be the easiest and fastest steel doors to install on the market. Whether you are fitting a single personnel door or a large double fire exit, our "Single Fix" design and adjustable frame system remove the complexity of traditional on-site joinery.

Delivered for Speed

To minimize site time and disruption, we supply our doorsets in the most installer-friendly format possible:

- Single Doors: Delivered fully assembled. The leaf is pre-hung in the frame with hardware (locks, panic bars, closers) factory-fitted and tested. Simply unwrap, position, and fix.

- Double Doors: For ease of manual handling, larger double doorsets may be supplied with the leaves separate from the frame. However, the frame is pre-prepared with all hinge points and striker plates for rapid on-site assembly.

The "Easy-Fit" Adjustable System

Structural openings are rarely perfect. All Robust doorsets feature a unique built-in adjustment system that handles site imperfections without the need for fiddly packers or shims.

1. Adjustable Fixing Feet

Each jamb is fitted with 4 adjustable fixing feet (8 per single door, 8-12 per double). These allow you to:

- Level the frame quickly using a 12mm hex key (supplied).

- Wind the feet out to grip the structural reveal securely, holding the frame in place while you check for plumb.

- Create a rock-solid fixing point without distorting the frame profile.

2. Variable Sub-Frame

The steel sub-frame features a "C" section tolerance channel that accommodates wall variations of -0mm to +30mm. This ensures:

- If your brickwork is uneven or the opening is slightly tapered, the frame expands to fill the gap.

- You achieve a continuous, secure fixing into the substrate without large, unsightly gaps to seal.

General Installation Steps

Step 1: Positioning

- Single Doors: Place the fully assembled unit into the structural opening.

- Double Doors: Assemble the frame (if supplied in parts) and position it in the opening first. Ensure the header is level before hanging the leaves.

Step 2: Adjustment & Levelling

- Use the 12mm hex key to wind out the adjustable feet until they grip the wall.

- Critical Check: Ensure the hinge jambs are perfectly plumb (vertical) in both planes using a long spirit level. If the frame is twisted, the door will not latch correctly.

- For double doors, ensure the frame header is perfectly level to prevent the leaves from misaligning at the meeting point.

Step 3: Fixing

- Drill through the center of the adjustable feet into the masonry or steelwork.

- Secure with appropriate fixings (e.g., 100mm x 10mm concrete bolts or heavy-duty tech screws).

- Test: Open and close the door(s) to check for smooth operation and correct latching before final tightening.

Step 4: Sealing

- Apply a fire-rated silicone or intumescent mastic around the entire perimeter of the frame (internal and external) to ensure fire and weather integrity.

- If a threshold is fitted, ensure it is bedded on sealant to prevent water ingress.

Handling Advice

- Weight Warning: Steel doors are heavy. A single leaf can weigh 50kg - 80kg.

- Single Doors: Use a mechanical lifter or a two-person team.

- Double Doors: We strongly recommend separating the leaves from the frame before moving to the installation point to reduce lifting weight.

- Storage: Always store doorsets upright on timber bearers in a dry, covered area. Never lay them flat on uneven ground or expose them to rain before installation.

WarrantySamson Doors Warranty (Robust UK Products)

As a premier supplier of Robust UK steel doorsets, Samson Doors provides a comprehensive warranty that covers your product against manufacturing defects and corrosion. This guarantee assumes that the doorset has been installed, used, and maintained in accordance with the manufacturer's instructions.

Anti-Corrosion Warranty

Thanks to the superior Magnelis® steel construction used by Robust UK, we are able to offer an industry-leading anti-corrosion warranty. The length of this warranty depends on the environmental classification of the installation site:

- Magnelis® Steel Doors:

- 10-Year Warranty: For locations classified as C1 to C3 (Low to Medium pollution/humidity, e.g., rural areas, standard urban sites).

- 5-Year Warranty: For locations classified as C4 (High pollution/industrial areas or coastal zones).

- 3-Year Warranty: For locations classified as C5 (Very high pollution/marine environments).

- Aluzinc Steel Doors:

- 24-Month Warranty: Standard cover for Aluzinc models.

- Extended Warranty: Available if an enhanced Polyester Powder Coated (PPC) finish is specified at the point of order.

Important Exclusion: The anti-corrosion warranty applies specifically to the door leaf and frame components manufactured from Magnelis®. Ancillary components (such as vision panels, louvres, and handles) are excluded unless additional protection was agreed upon prior to manufacture.

Manufacturing & Component Warranty

- Doorset Structure: 24-Month Warranty against manufacturing defects (e.g., bond failure, weld failure).

- Hardware & Ironmongery: 12-Month Manufacturer's Warranty on all locks, handles, closers, and panic hardware, subject to normal use and maintenance.

Conditions of Warranty

For any claim to be valid, the following conditions must be met:

- Maintenance Log: A documented cleaning and maintenance regime must be kept, recording the frequency of cleaning and the products used. This log must be submitted with any warranty claim.

- Correct Installation: The product must have been installed correctly according to the provided fitting instructions (including correct frame adjustment and sealing).

- Reporting Period: Any manufacturing defects visible on delivery (e.g., scratches, dents) must be reported to Samson Doors in writing within 3 working days of receipt, accompanied by photographic evidence of the goods on the original pallet.

Warranty Exclusions

The warranty does not cover defects or damage resulting from:

- Abuse & Neglect: Damage caused by misuse, vandalism, or lack of routine maintenance (e.g., failure to lubricate hinges/locks).

- Chemical Damage: Use of corrosive cleaning agents, solvents, or abrasive pads on the door finish.

- Installation Errors: Issues arising from poor fitting (e.g., frame twisted out of square, insufficient fixings).

- External Factors: Damage from storms, floods, or impacts not considered normal usage.

- Unauthorised Modifications: Fitting of third-party hardware or cutting into the door leaf/frame without prior written approval.

- Fair Wear & Tear: Normal degradation of consumable parts (e.g., seals, keys) over time.

Claims Procedure

In the unlikely event of a fault, please follow this procedure:

- Contact Samson Doors in writing immediately upon discovery of the defect.

- Provide your original order reference, a detailed description of the issue, and clear photographs.

- If required, the defective part may need to be returned for inspection.

- Where a valid claim is accepted, Samson Doors (in conjunction with Robust UK) will repair or replace the defective component or product at our discretion.

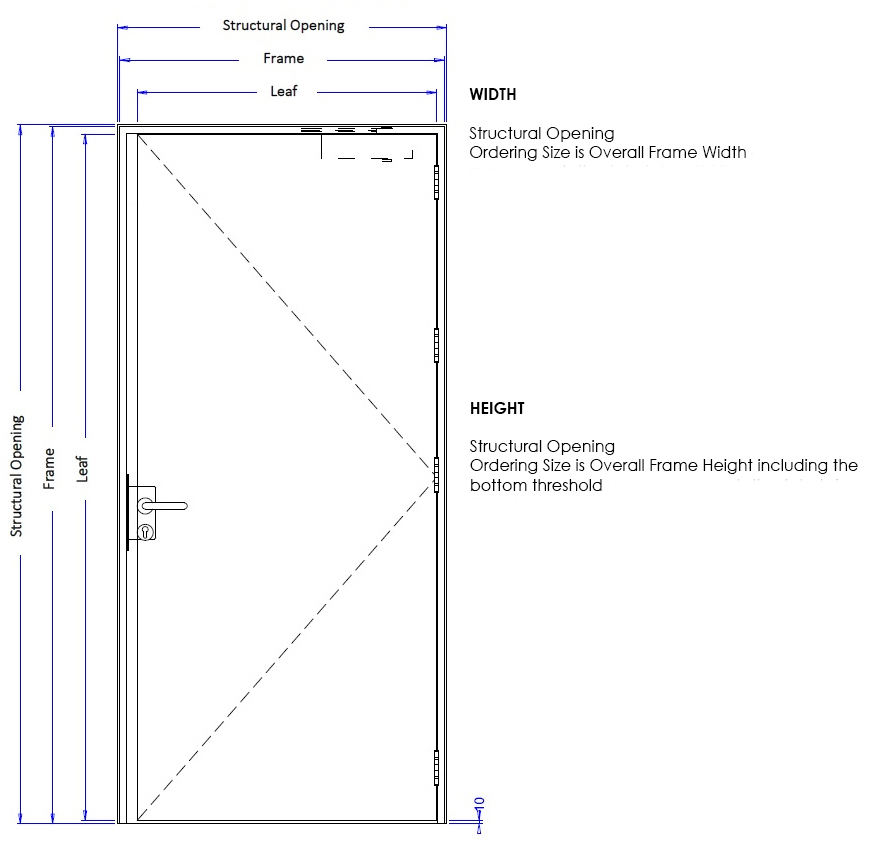

MeasureHow to Measure for Your Robust Steel Doorset

Getting the measurements right is critical for a smooth installation. Please follow this guide carefully to determine the correct ordering size for your Robust Outa-Dor. Remember: we manufacture to the exact dimensions you order, with no automatic tolerances deducted.

1. Measure the Structural Opening

Measure the raw aperture (brick-to-brick) where the door will be installed. Do not measure the existing frame.

- Width: Measure at the Top, Middle, and Bottom of the opening. Record the smallest dimension.

- Height: Measure at the Left and Right sides from the lintel to the finished floor level. Record the smallest dimension.

- Squareness: Check the diagonals (corner to corner) to see if the opening is square.

2. Calculate Your Ordering Size

The ordering size is the OVERALL size of the complete doorset unit (including the door leaf, frame, and threshold).

- Width Calculation: Take your smallest structural width and deduct your fitting tolerance (e.g., 10mm total).

- Height Calculation: Take your smallest structural height and deduct your fitting tolerance (e.g., 10mm total).

Example:

If your structural opening is 1000mm (W) x 2100mm (H):

Subtract 10mm from the width (5mm each side) → Order Width: 990mm

Subtract 10mm from the height (5mm top + 5mm bottom) → Order Height: 2090mm

The "Outa-Dor" Advantage: Built-in Tolerance

One of the key benefits of the Robust Outa-Dor is its unique adjustable fixing frame.

- Variable Sub-Frame: The frame design includes a variable "C" section that can accommodate up to 30mm of tolerance (+0mm / +30mm).

- Why this matters: If your brickwork is uneven or the opening isn't perfectly square, the frame can expand to fill the gaps. This makes the Outa-Dor significantly more forgiving to install than standard fixed-frame steel doors.

Important Reminders

- Metric Only: Please provide all measurements in millimetres (mm) to ensure accuracy.

- Check the Drawing: We will always create a technical drawing based on your ordering dimensions. This will be sent to you for final approval before manufacturing begins.

- Include the Threshold: Remember that the "Overall Height" includes the threshold. If you are recessing the threshold into the floor, you must account for this in your measurements.

Please refer to the diagram below for a visual guide on where to take your measurements.