Choosing and Ordering a SeceuroDoor Roller Shutter Door

The SeceuroDoor range of industrial and commercial roller shutter doors has been developed over many years to provide reliable operation and compliance with current requirements for electrically operated doors.

You can choose from:

- Single skin steel doors for more basic requirements

- Double skinned insulated steel doors for higher performance (with options for higher speed/high usage)

- Security-rated SeceuroDoor models with tested/certified burglar-resistant performanc

How to choose the Right Door Model...

The range is split into pre-specified roller door models to make it easier to select the correct product and price it online.

1. Insulated or non-insulated curtain

Non-insulated (single skin)

SeceuroDoor 75 models use single skin galvanised steel curtains. They are a practical choice where insulation is not required.

Insulated (double skinned)

SeceuroDoor 77, 95 and 100 models use double skinned steel curtains. These doors offer insulation, improved rigidity and quieter operation. Because the slats are heavier they typically sit down firmly when closed, which helps reduce wind rattle, and they also provide greater overall strength.

If your door will be opened frequently during the day, insulated models can be specified with higher speed and/or higher usage motor options where appropriate.

2. Do you need a security rating (SR1 / SR2)?

If your insurer, landlord, architect or security assessment specifies a security rating, select a security-rated model rather than a standard door upgrade.

Security-rated models available:

- SeceuroDoor 7501 – SR1 rated door (security-rated, non-insulated)

- SeceuroDoor 7502 – SR2 rated door (higher security rating than SR1, non-insulated)

- SeceuroDoor 9501 – SR1 rated insulated door (security-rated plus insulation)

If you are unsure which rating you need, confirm the required rating/standard before ordering and include it with your enquiry so we can quote the correct certified specification.

3. Single phase or three phase electric motor

We typically offer three motor drive options depending on door size, duty level and the power supply available:

- Single phase 240V tube motor A compact motor housed inside the barrel. Best suited to smaller doors with low daily usage.

- External mounted single phase motor A step up in performance and duty, commonly used where more operations per day are required. Available as chain drive or direct drive (see below).

- Three phase motor Used for larger doors and/or where higher power, higher speed and/or high usage is required.

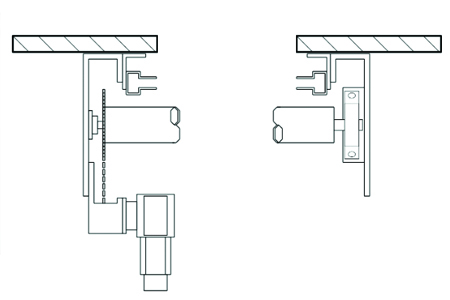

4. Chain drive or direct drive motor arrangement

Many industrial roller shutters can be supplied with either chain-driven motors or direct-drive motors. The best option often depends on the installation space available.

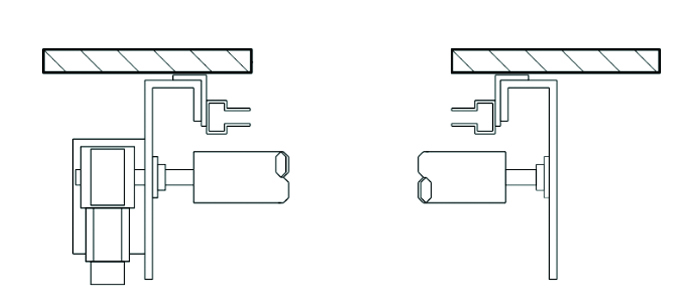

Direct drive (outboard)

A direct-drive motor mounts outside the endplate and drives the barrel directly. It typically has fewer moving parts and is usually the preferred option where space and specification allow. Direct drive is also required where a higher speed or high usage specification is needed within this range.

Chain drive (inboard)

A chain-driven motor is usually positioned inboard within the endplates. This can be useful where outboard space is limited, but it requires adequate internal side room.

Tube motors

Tube motors sit inside the barrel and are generally used for smaller to medium doors with lower usage requirements.

|

|

|

| Inset Inboard motor position | Inset Outboard motor position |

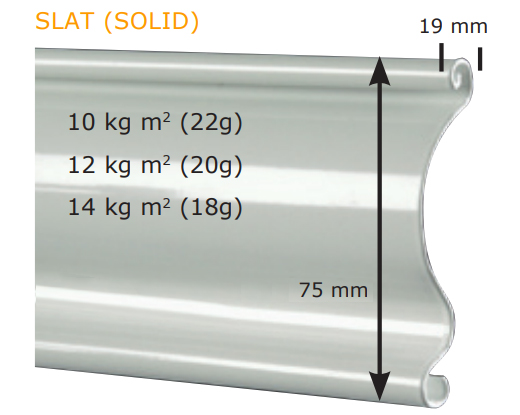

5. Steel curtain thickness (SeceuroDoor 75)

Within SeceuroDoor 75, door models are also split by steel curtain thickness (for example 22 gauge and 20 gauge, with heavier options available on request).

- Thicker steel increases strength and weight

- Heavier gauges can allow larger size limits depending on the model

- Thicker curtains typically cost more but provide a stronger overall curtain

How to order and specify your SeceuroDoor

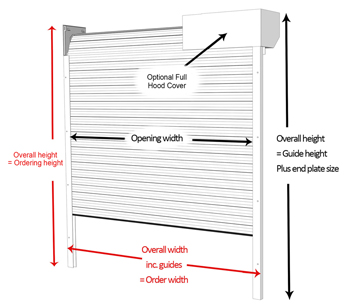

1. Choose the Width and Height (how sizes are taken)

Traditional industrial roller doors in our online shop are ordered by “daylight opening sizes”:

- Width between the guides

- Height to the top of the guides

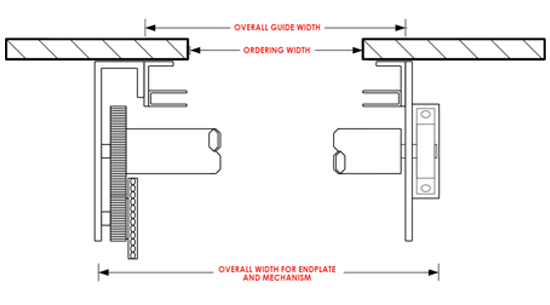

Continental build doors are ordered using “overall width” and “overall height” to include:

- Guides

- Endplates

- Hood/cover (where applicable)

Traditional builds are commonly fitted internally to the face of an opening. Continental builds are often used for between-opening installations, but can also be fitted behind the opening or to the outside face where required.

2. Choose the Motor Side

Motor side is chosen when viewing from inside the building looking out. This is typically the side where power and controls will be positioned, including any manual emergency override associated with the motor.

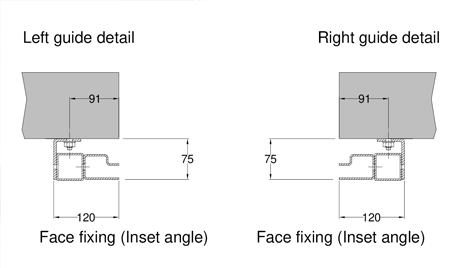

3. Choose the Guides and Fitting Arrangement

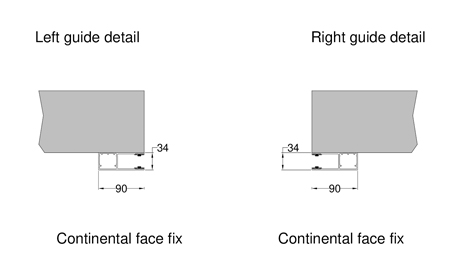

Continental set-up

This typically uses a consistent guide arrangement (commonly a one-piece guide) set in line with the endplates. It is well suited to between-aperture installations.

Traditional set-up

This provides more options for guide/angle arrangements. The best choice depends on the structure (steelwork, brickwork or blockwork) and the most suitable fixing positions.

Side room and drawings

The motor side often requires more side room than the non-motor side. We will provide an approval drawing before manufacture so you can confirm side room, clearances and fixing details.

Continental Set Up |

|

4. Endplate and roll fitting position (face fit or reveal fit)

Specify whether the guides and curtain are:

- Face fixed (inside face), or

- Reveal fixed (under the lintel)

If you fit the roller door underneath a lintel, you will normally need a hood cover (unless a fascia is being formed by others), because the roll/curtain is otherwise visible and exposed from outside.

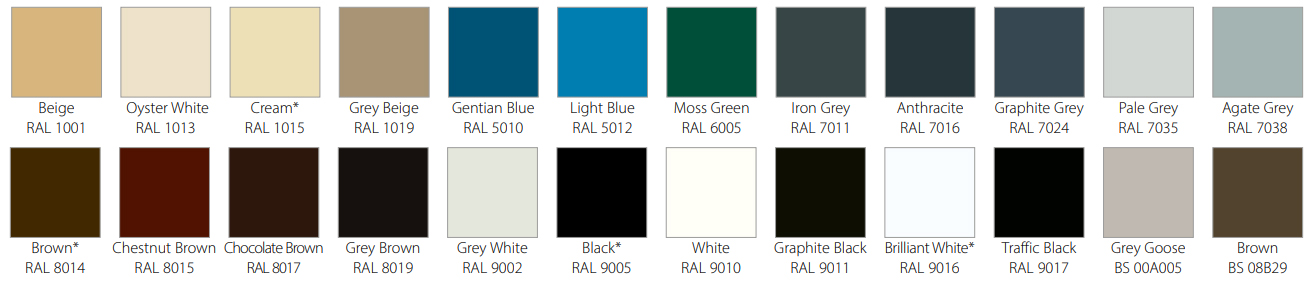

5. Door Curtain Colour and Finish

Choose from the colours available for the selected model. Depending on specification, different finish options may be available for the external face (for example plastisol or powder-coated), and prices can vary by finish and colour.

6. Bottom rail selection (and safety edge where required)

The bottom rail can vary by application. If you choose auto-closing and/or remote control, a safety edge system is typically required and is normally integrated into the bottom rubber seal arrangement.

For manual doors and simple “hold-to-run” operation, a standard bottom rail is usually sufficient.

7. Door Control Method

Manual doors

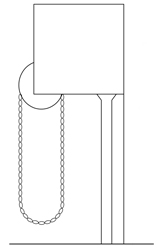

Manual operation uses a chain pulley system or a spring-assisted push-up/pull-down arrangement, so powered control packages do not apply.

Electric doors

We can supply standard control packages to suit most requirements, as well as more bespoke control options (such as timers, radar detectors, or integration with other systems) on request.

Control package 1 Wall-mounted push button control with “hold-to-run” (deadman) operation. In many cases this does not require a safety edge, provided the controls are in direct line of sight of the door during operation.

Control Package 2 Wall-mounted control with impulse operation and auto-close. This requires a safety edge system, which is included.

Control Package 2 Wall-mounted control with impulse operation and auto-close. This requires a safety edge system, which is included.

Control package 3 As package 2, plus remote controls and safety edge detection. Additional safety devices (such as an infrared beam) may be recommended following a site assessment, particularly where the door is adjacent to areas used by pedestrians or vehicles.

Special Controls - POA If you need more advanced automation or integration, contact us to discuss the requirement and we will advise the best control solution.

8. Control Accessories

We offer common accessories such as external key switches and digital keypads (typically used alongside appropriate safety systems, depending on the control method).

If you need an accessory not listed, please contact us with details and we will advise and price accordingly.