- Description

- Application

- Specification

- Installation

- Warranty

- Measure

Gliderol Series B Manual Light Industrial Roller Door

Overview

The Gliderol Series B Light Industrial is a robust, manually operated continuous curtain roller door designed for commercial and industrial applications where reliability and simplicity are paramount. As a cost-effective alternative to heavy-duty industrial shutters, it offers a secure, lightweight, and easy-to-operate solution for openings up to 5 metres wide.

This model is specifically designed for manual operation, utilising a finely balanced spring-assisted mechanism or a heavy-duty chain hoist system depending on the door size.

Construction & Materials

Built to withstand the rigours of daily commercial use, the Series B features a high-quality construction specification:

- Curtain Material: Manufactured from strong 0.45mm gauge steel continuous sheet curtain.

- Finish Options: Available in a durable Plastisol colour coating (leathergrain effect) in a wide range of standard colours. A basic Galvanised Steel finish is also available for purely functional applications where colour is not required.

- Reverse Coat: The interior face of the curtain is painted with a protective two-layer grey primer coating [file:44].

- Guides: Supplied with heavy-duty 50mm wide windlock guides as standard, ensuring the curtain is held securely within the tracks even during adverse weather conditions [web:51].

Manual Operation Methods

The Series B operates smoothly thanks to its unique "spring-assisted spindle assembly," which balances the weight of the curtain for effortless movement [web:48].

- Push-Up / Pull-Down: For smaller sizes, the door can be easily operated by hand, lifting and lowering with minimal effort due to the precise spring tensioning.

- Chain Hoist (Geared): For larger doors (typically over 3000mm high or wide), a planetary geared chain hoist system is supplied [file:44]. This allows the operator to open and close the door easily from ground level using a continuous haul chain, providing mechanical advantage for heavier curtains.

Installation Requirements

This is an uninsulated steel roller door designed for Internal Face Fitting only. Please note the following critical installation details:

- Mounting: Must be fitted to the inside face of the structural opening.

- Sideroom: A minimum sideroom of 250mm is required on each side to accommodate the support brackets and guides [web:51].

- Headroom: Sufficient headroom is required to accommodate the curtain roll (drum). Larger doors will have a larger roll diameter; typically, 430mm to 550mm of headroom is recommended depending on height [web:57].

- Wind Resistance: While the door features windlock clips to secure the curtain in the guides, it is not recommended for extremely exposed locations with high wind speeds.

Suitability & Application

The Series B is an ideal choice for:

- Low to Medium Usage: Perfect for openings requiring up to approx. 20 operations per day.

- Warehouses & Units: Excellent for securing goods-in/out entrances, agricultural buildings, and workshops where thermal insulation is not a primary requirement.

- Max Dimensions: Suitable for openings up to 5000mm Wide x 4900mm High.

Note: If you require electric operation, please view our Gliderol Series B Electric Model.

The Gliderol Series B roller shutter door is ideal for light industrial/commercial use.

It is designed to face fit to the inside of any aperture and should not be considered for installartion externally or inbetween an opening without creating a false face to fit to.

Technical Specification: Gliderol Series B (Manual)

Curtain Construction

The Gliderol Series B features a continuous sheet curtain design, engineered for durability and smooth operation:

- Material: 0.45mm gauge high-tensile steel curtain.

- Profile: Deep ribbed profile for added strength and rigidity across wider spans.

- Bottom Rail: Heavy-duty aluminium bottom rail with a specially designed weather seal. This reinforces the bottom of the curtain against forced entry while preventing leaves, dust, and rain from entering the building.

- Guides: 50mm wide heavy-duty galvanised steel "windlock" guides. These feature integrated clips to hold the curtain securely within the track during windy conditions [web:51].

Operation Mechanisms

The manual operation method is determined by the size and weight of the door to ensure compliance with health and safety manual handling guidelines:

1. Spring Assisted (Push-Up)

Used on smaller doors, this system utilizes a counterbalanced spring assembly within the barrel. It allows the door to be easily lifted and lowered by hand with minimal effort.

2. Chain Hoist Operation (Geared)

Standard on larger doors (typically over 9m² or 3000mm high/wide). This system features:

- Planetary Gearing: A high-efficiency gear system (ratio approx. 4:1) that reduces the physical effort required to lift the door [file:44].

- Chain Guide: A dedicated anti-slip chain guide ensures the haul chain remains securely engaged with the chain wheel, preventing slippage during operation [file:44].

- Cleat: A wall-mounted chain cleat is supplied to secure the chain when not in use.

Colour & Finish Options

The door is available in a durable HP200 Plastisol finish (leathergrain effect) which offers excellent weather resistance and colour retention. A basic Galvanised Steel finish is also available.

Standard Plastisol Colours:

- ⚪ White

- ⚫ Black

- 🔘 Anthracite Grey

- 🟤 Vandyke Brown

- 🟢 Olive Green

- 🌲 Juniper Green

- 🔴 Burgundy

- 🔵 Navy Blue

- 🌾 Honesty (Cream)

- 🌫️ Goosewing Grey

- 🌑 Merlin Grey

- 🪵 Mahogany Woodgrain

Installation & Structural Requirements

Mounting Type: Internal Face Fit Only.

- Sideroom: Minimum 150mm - 250mm required either side (depending on operation type) [web:51].

- Headroom: Requires between 430mm and 550mm headroom above the opening height to accommodate the curtain roll (drum size varies by door height).

- Structural Fixings: Must be fixed to a suitable structural support (steel, blockwork, or brick). Not suitable for hollow bricks or thermal blocks without specialist fixings.

Warranty & Compliance

All Gliderol Series B doors are:

- CE Marked: Fully compliant with European safety standards (EN 13241-1).

- Warranty: 2-year manufacturer's warranty on all mechanical parts and 10-year limited warranty on the Plastisol finish (subject to location/maintenance) [web:50].

- Made to Measure: Custom manufactured to your exact opening dimensions.

Installation instructions provided with every door ordered.

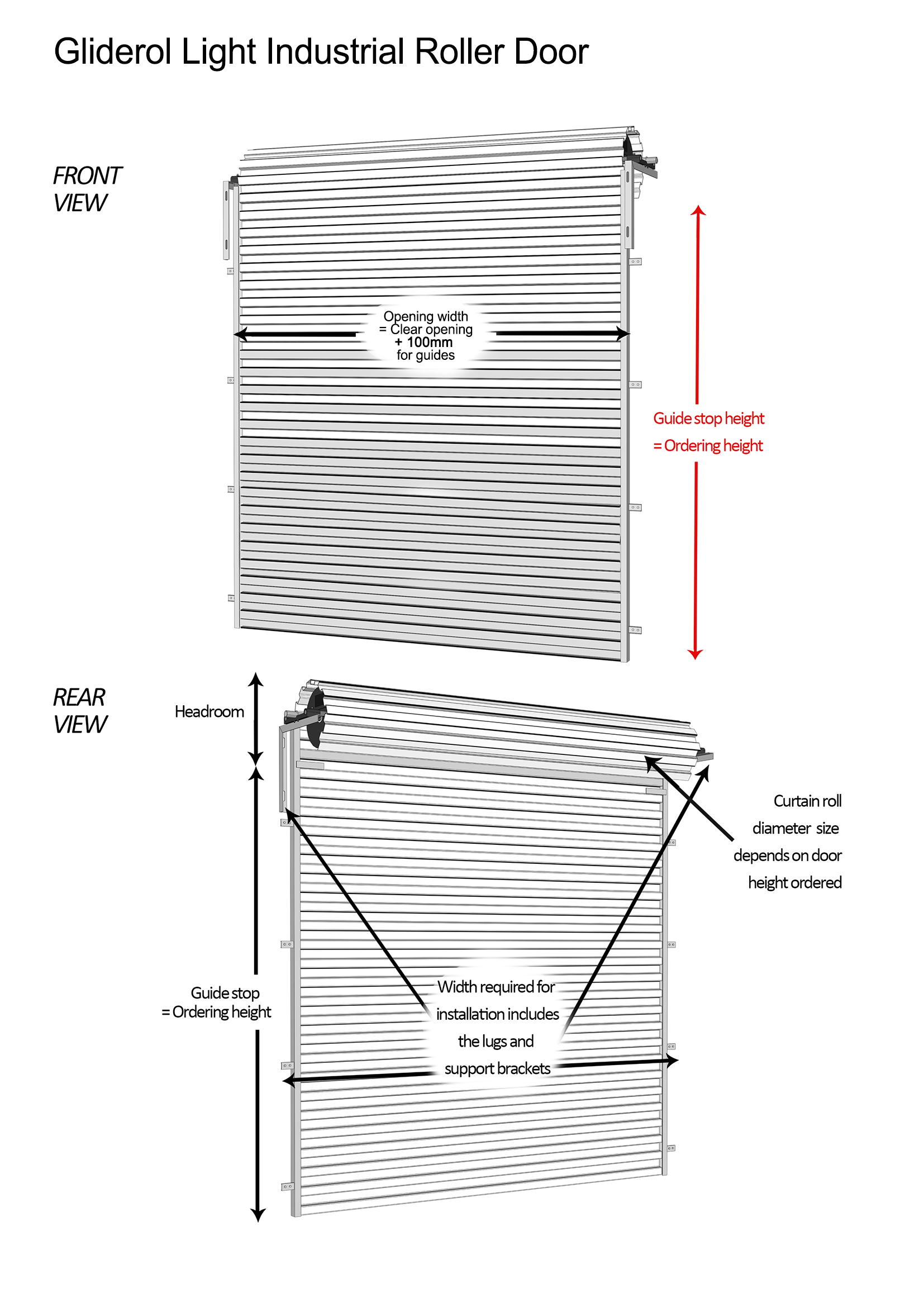

The ordering width is the daylight opening between the guides PLUS 100mm and the ordering height is the height of the side guide rails NOT including the roller curtain which will vary from 460 - 530mm depending on the door height.

Side room required for installation will vary from 150 - 225mm depending on the height of the door and the mechanism supplied for the chain operation.

• Light Industrial/Commercial use - 10 years corrosion free on door panel excludes paint surface rubbing or fading..

1 year on the lock and face plate, spring, bottom roller, weatherseal and polyglide, if fitted by an authorised Gliderol Distributor or Gliderol Technician.

• Industrial/Commercial use - 1 year on the lock and face plate, spring, bottom roller, weatherseal and polyglide, if fitted by an authorised Gliderol Distributor or Gliderol Technician.

The manufacturer strongly recommends that all Gliderol products be serviced by an authorised Gliderol Distributor or Gliderol Technician every 12 months to ensure longevity of the products’ life. Failure to do this may result in any warranty being invalid.

Warranties of 2 years electrical, 6 years mechanical and 10 years paint finish apply to all Gliderol doors (except Mini Roller Garage Doors).

PRODUCT WARRANTY CONDITIONS

Warranty Conditions

1. Subject to the under mentioned specific limitations and exceptions, the Manufacturer warrants all new doors, motors and electronic components of its

manufacture to be free from defect in workmanship under normal use and service and further warrants all installation carried out by the Manufacturer or by its nominated installers to be free from defects and workmanship its obligations hereunder being limited to making good any such defect PROVIDED THAT notice of any claimed defect in material workmanship in or resulting from installation of any door shall have been given to the Manufacturer within the period from date of installation as prescribed in the schedule hereto.

2. This warranty does not apply to any defect, loss or damage arising or caused directly or indirectly by or as a result of;

(i) Any masonry rendered or other surfaces cracking or collapsing during installation of the door.

(ii) Any defect or deterioration of timber including drying out after installation.

(iii) Any weakening or collapse of the structure to which the doors are affixed occurring any time after installation.

(iv) Any damage to or deterioration in the condition of the doors occurring in transit by customer nominated or appointed carrier or occurring after delivery and prior to installation.

(v) Any defect (including defects in component parts or accessories) rising from or attributable to the failure to carry out normal preventive maintenance or adjustment.

(vi) To any additional defect damage or deterioration arising from or attributable to the operation of the door after it is known to be defective.

(vii) Any door being installed within 800 metres of the sea or other body of water of equivalent or greater salt concentration or in an area subject to industrial fall out.

(viii) Any fault or surge in customer’s electricity supply.

(x) The door striking an immovable object during travel.

(xi) Garage doors should be inspected upon delivery and viewed in natural light (not direct sunlight) from a standard distance of 3 metres to view their overall appearance. From this distance the door panel should appear free from marks or distortion, stains, blemishes, indentations or scuffs. If any marks are only visible within 3 metres they will not be considered under warranty.

3. Items excluded from warranty;

(i) Batteries

(ii) Fuses

(iii) Globes

(iv) Sensitivity adjustments

(iiv) Minor factory repairs

4. While Gliderol doors are long lasting and hard wearing under normal conditions this warranty does not extend to inherent defects in steel or other material used in the manufacture. The Manufacturer will however, procure and assign to the customer the benefit of the warranty of the manufacturer of the steel or other material.

5. If Manufacturer has at request of customer procured painting, powder-coating or other surface application to its product this warranty does not extend to such painting, powder-coating or other surface application. For this purpose Manufacturer at all times acts as agent of customer. Manufacturer may as a

service to the customer but without any legal obligation to do so, assist customer to obtain redress in respect of any defect.

6. The Manufacturer reserves the right to touch up on site the paint finish and or pre-painted surfaces on its range of garage doors but no responsibility will be taken for the possibility of any paint rubs, scuffing etc on the internal wash coat finish or external painted surface.

7. Proof of purchase MUST be provided to the manufacturer at time of warranty claim. If proof is not available any warranty may be invalid.

Measuring and Ordering Guide

Important: The Gliderol Series B is designed for Internal Face Fixing only. The measurements you provide will be the manufacturing size of the door, not the size of your opening. Please follow the steps below carefully.

1. Calculating the Ordering Width

The Ordering Width for this door is the Total Width Over the Guides. To calculate this, you must measure your daylight structural opening and add an overlap for the guides.

- Measure: Measure your structural opening width in three places (top, middle, bottom).

- Select: Take the widest of these three dimensions.

- Calculate: Add 100mm to this dimension.

Formula: Widest Structural Opening + 100mm = Ordering Width

Example: If your structural opening is 4000mm wide, your Ordering Width is 4100mm.

Why add 100mm? This provides a 50mm overlap on each side, which is required to accommodate the width of the guides and the fixing lugs are an additional width requirement - see below .

2. Side Room Requirements (Clearance)

While the guides only overlap the wall by 50mm on each side, you must ensure you have sufficient physical space adjacent to the opening to accommodate the drive mechanism and mounting brackets.

- Motor/Chain Side: Requires between 150mm - 225mm clearance (depending on door height and mechanism type).

- Non-Drive Side: Requires approximately 75mm - 100mm clearance.

Motor Handling: The side of operation (Left or Right) is always chosen as viewed from inside looking out.

3. Determining the Ordering Height

The Ordering Height for the Series B is the Guide Height only. It represents the length of the side runners.

- Warning: The Ordering Height does NOT include the roller curtain roll located above the guides.

- Headroom Required: You must ensure you have sufficient headroom above the top of the guides for the door curtain to roll up into. This varies between 460mm and 530mm depending on the total height of the door.

Example: If you order a height of 3000mm, you will receive 3000mm long guides. The total space required from floor to ceiling will be 3000mm + approx. 480mm for the roll.