DescriptionHormann HS 5015 PU H 42/67 High Speed Sectional Door

The Flexible Solution for High-Level Services

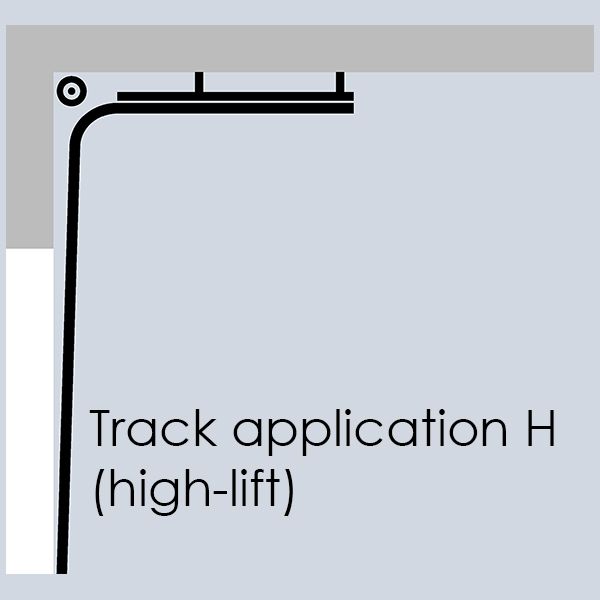

The Hormann HS 5015 PU H is an engineered high-speed sectional door designed specifically for industrial buildings where services, cranes, or pipework run close to the lintel. Unlike standard vertical or horizontal track systems that can clash with overhead obstructions, the "High-Lift" (H) track application allows the door panels to rise vertically first, then divert horizontally at a higher level to follow the roofline or clear essential infrastructure.

This flexibility makes it the ultimate choice for logistics centres and manufacturing plants where maximizing internal volume is critical, ensuring your door mechanism doesn't waste valuable space or interfere with overhead gantry cranes, ventilation ducts, or lighting arrays.

Adaptable "High-Lift" Track Mechanism

The "H" track configuration is the key to this door's versatility. By extending the vertical tracks higher up the wall before curving into the horizontal run, the door parks its insulated sections well above the opening height. This setup requires a minimum headroom of 750mm (depending on size), providing a perfect balance between clearance and compact operation.

The movement is controlled by a precision belt mechanism with counterweights. This system is superior to standard spring-tensioned cables because the counterweights provide constant, non-degrading balance throughout the door's travel. The result is an exceptionally low-wear system that is quieter, smoother, and requires less maintenance than traditional spring-balanced doors, even after years of high-cycle operation.

Two Thermal Performance Levels

The HS 5015 PU H allows you to select the level of insulation that matches your building's energy strategy:

- Standard 42mm Sections: Ideal for general warehousing and logistics, providing robust security and good thermal separation (U-values up to 1.04 W/m²K).

- Enhanced 67mm Sections: For facilities where temperature control is critical—such as cold storage access or heated production zones—the 67mm option offers superior thermal efficiency with U-values as low as 0.64 W/(m²·K).

Both versions feature double-skinned, hot-galvanised steel sections with a rigid PU foam core and integrated thermal breaks. For the ultimate in energy savings, the optional ThermoFrame can be added, decoupling the frame from the masonry to reduce thermal bridging by up to a further 15%.

Speed and Efficiency

Despite its robust construction, the HS 5015 PU H is built for speed. Powered by a high-performance frequency converter (FU) control, it achieves opening speeds of up to 2.5 m/s. This rapid action minimises the time the door stays open, drastically reducing air exchange and helping you maintain consistent internal temperatures while keeping traffic flowing freely.

Key Features at a Glance

- Flexible Track Routing: "High-Lift" design allows the door to clear overhead obstacles like crane tracks or supply lines.

- Low-Wear Mechanism: Belt and counterweight system ensures smooth, long-lasting operation with minimal maintenance.

- Superior Insulation Options: Choose between 42mm or 67mm thick sections to suit your thermal requirements.

- High Wind Resistance: Capable of withstanding wind loads up to Class 5, making it suitable for exposed external locations.

- Smart Safety: Integrated non-contact light grille monitors the closing zone, protecting staff and equipment without vulnerable bottom-edge sensors.

ApplicationIdeal Applications for the HS 5015 PU H

Solving Overhead Obstruction Issues

The HS 5015 PU H (High-Lift) is specifically engineered for industrial environments where the space immediately behind the lintel is congested. Standard sectional doors often conflict with infrastructure installed close to the opening, but the High-Lift track allows the door panels to travel vertically past these obstacles before turning horizontally.

This makes it the primary choice for:

- Manufacturing Halls with Gantry Cranes: Where crane rails run close to the external walls, the door tracks can be routed higher up to prevent collisions and maximise crane travel.

- Facilities with Complex Services: Buildings with significant HVAC ducting, industrial pipework, or cable trays running directly above the doorway.

- Mezzanine Floor Installations: Where structural steelwork or walkways are positioned at a specific height that blocks standard horizontal tracks.

High-Intensity Logistics

Thanks to the unique belt and counterweight mechanism, this door is exceptionally durable and quiet. Unlike spring-balanced doors that require regular tensioning and have a limited cycle life, the counterweight system maintains perfect balance indefinitely.

This durability makes the HS 5015 PU H ideal for:

- 24/7 Distribution Centres: Where doors are in constant motion and downtime for spring repairs is unacceptable.

- Automotive Production Lines: Where high reliability and low maintenance intervals are critical for "just-in-time" processes.

- Noise-Sensitive Areas: The belt drive eliminates the clatter of chain drives and steel springs, making it suitable for logistics areas near offices or residential zones.

Temperature-Controlled Environments

With the option to upgrade from 42mm to 67mm thick insulated sections, this door serves as a vital component in energy management strategies.

- Cold Chain Logistics: The 67mm version (U-value approx. 0.64 W/m²K) provides the thermal break necessary for chilled warehouses, keeping energy costs down while allowing rapid forklift access.

- Heated Workshops: Prevents heat loss in winter, maintaining a comfortable working environment for staff located near loading bays.

- Food Processing: The rapid opening speeds reduce the ingress of pests and dust, while the smooth Micrograin surface is easy to wipe down.

External Security Barriers

Unlike fabric high-speed doors that offer no physical security, the HS 5015 PU H provides a solid wall of steel when closed. It is perfect for:

- External Goods-In/Out Bays: Acting as the sole perimeter door that offers speed during the day and secure locking at night.

- Secure Compounds: For high-value storage areas requiring visual deterrents and resistance to forced entry.