DescriptionHormann HS 5015 PU N 42 Insulated High Speed Sectional Door

The Space-Saving Solution for Limited Headroom

The Hormann HS 5015 PU N 42 is the perfect high-speed sectional door for industrial buildings where lintel space is at a premium. Requiring just 480mm of headroom, this innovative design makes it possible to install a fully insulated, high-performance door in locations where traditional sectional or spiral doors simply won't fit.

Whether you're retrofitting a door into an existing building with low ceilings, working around structural beams, or dealing with mezzanine floors that restrict your vertical clearance, the HS 5015 PU N delivers exceptional speed, security, and thermal performance without demanding excessive structural modifications.

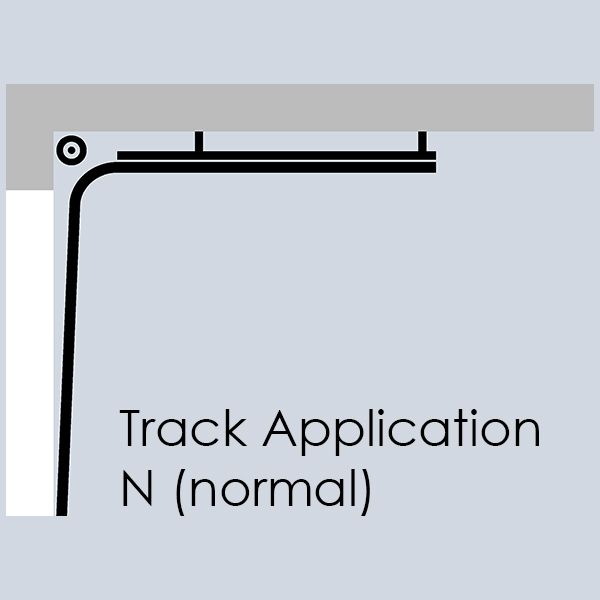

Normal Track Application (N) - Engineered for Compact Installations

The defining feature of the HS 5015 PU N is its Normal Track Application, a space-efficient mechanism designed specifically for situations where headroom is severely restricted. Unlike vertical or high-lift track systems that require substantial ceiling height, the Normal track guides the insulated sections into a horizontal run positioned immediately above the door opening.

As the door opens, a precision chain mechanism with spring compensation lifts each section from the vertical plane and transitions it smoothly into the horizontal track overhead. The spring compensation system is critical: it counterbalances the weight of the steel sections throughout the entire opening cycle, ensuring the motor only needs to overcome friction rather than the full gravitational load of the door. This results in faster operation, reduced energy consumption, and significantly extended component life.

How the Chain and Spring Mechanism Works

The HS 5015 PU N uses a robust chain-driven operator mounted to one side of the door opening. As the chain pulls the bottom section upwards, the spring compensation system engages, providing a constant counterforce that supports the weight of the ascending panels. Each 250mm-high section is linked by heavy-duty hinges that allow the panels to articulate smoothly as they transition from vertical to horizontal.

Once the door is fully open, all sections are stacked horizontally in the track directly above the lintel, taking up minimal ceiling space while keeping the entire opening completely clear for vehicle and pedestrian traffic. The compact 480mm headroom requirement makes this one of the most space-efficient insulated high-speed doors available on the market.

Key Advantages of the Normal Track System

- Minimal Headroom Requirement: Just 480mm clearance needed above the door opening—ideal for low-ceiling buildings or installations beneath mezzanine floors.

- Spring-Assisted Operation: Reduces motor load and wear, ensuring quiet, smooth door travel and long-term reliability.

- Cost-Effective Installation: Avoids the need for expensive structural alterations or ceiling reinforcements often required by high-lift systems.

- Faster Project Completion: Simpler installation process with fewer on-site modifications means reduced downtime during fitting.

Robust 42mm Insulated Steel Construction

Despite its compact mechanism, the HS 5015 PU N doesn't compromise on quality or performance. The door curtain is constructed from 42mm-thick, double-skinned hot-galvanised steel sections filled with rigid polyurethane (PU) foam and featuring integrated thermal breaks to prevent cold bridging.

Each section is precision-manufactured with a Micrograin textured exterior for a modern, professional appearance and a Stucco-textured interior for durability. The door is supplied in White Aluminium (RAL 9006) as standard, with over 200 RAL colours available to match your corporate branding or building aesthetic.

The 250mm-high sections provide excellent structural rigidity while maintaining the flexibility needed to navigate the track curves smoothly. The thermal breaks embedded within each section ensure that heat transfer through the door panels is minimised, delivering U-values of up to 1.04 W/(m²·K)—making this door highly effective in temperature-controlled environments.

Enhanced Thermal Performance with ThermoFrame

For facilities where energy efficiency is paramount—such as chilled warehouses, food production plants, or heated manufacturing areas—the optional ThermoFrame system can be specified. This thermally-separated frame assembly creates a barrier between the door structure and the building fabric, reducing heat transfer through the frame perimeter by up to 15%. When combined with the insulated sections, this significantly lowers heating and cooling costs while improving internal climate stability.

High-Speed Performance

The HS 5015 PU N is designed for busy industrial environments where rapid access is essential. Fitted with a frequency converter (FU) control system as standard, the door achieves opening speeds of up to 2.5 metres per second (depending on door size and configuration), with a closing speed of approximately 0.5 m/s.

The frequency converter delivers smooth soft-start and soft-stop functionality, eliminating the sudden jolts and vibrations common in older door systems. This not only protects the mechanical components from shock loads but also creates a safer, quieter working environment for staff operating near the door.

Integrated Safety Systems

Safety is built into every aspect of the HS 5015 PU N. The door is supplied as standard with an integrated safety light grille concealed within the side frame assemblies. This non-contact monitoring system uses infrared beams to detect any obstruction in the door's closing zone up to a height of 2500mm, immediately halting the door if a person, vehicle, or object is detected.

Unlike traditional bottom-edge sensors or photocells—which are vulnerable to damage from forklift impacts or require regular realignment—the light grille is fully protected inside the door frame and requires minimal maintenance. The system is fully compliant with DIN EN 13241-1 safety standards, ensuring your facility meets all current health and safety regulations.

SmartControl Monitoring as Standard

Every HS 5015 PU N is equipped with SmartControl, Hormann's intelligent door management system. This allows facility managers, maintenance engineers, or service technicians to access real-time diagnostic data via an online portal from any location worldwide.

SmartControl provides:

- Live Door Status: Instant visibility of whether the door is open, closed, or in motion.

- Cycle Counting: Track the number of opening and closing cycles to plan preventative maintenance before components reach end-of-life.

- Error Logging: Automatic recording of faults or operational issues with time-stamped data for troubleshooting.

- Remote Diagnostics: Service engineers can often identify and resolve control issues remotely, reducing expensive call-out fees and minimising downtime.

Optional Glazing for Natural Light

To introduce natural daylight into your facility and improve visibility through the door, optional Duratec glazing panels can be integrated into the door sections. These high-grade synthetic panes feature a special scratch-resistant coating that protects against damage from cleaning and industrial environments.

The double-glazed units are fitted into black synthetic glazing frames and can be easily replaced from the inside if damaged, thanks to removable glazing beads. This makes maintenance simple and cost-effective, avoiding the need for specialist contractors or complex disassembly.

Emergency Operation Options

In the event of a power failure, the HS 5015 PU N can be operated manually using the standard emergency hand chain, which engages the spring compensation system to allow the door to be opened by hand with minimal effort.

For critical applications—such as emergency vehicle access, production areas that cannot afford downtime, or facilities operating 24/7—an optional UPS (Uninterruptible Power Supply) system can be specified. This automatically powers the door during mains failures, ensuring uninterrupted operation even during outages.

Made to Measure

Every HS 5015 PU N door is custom-manufactured to your exact site dimensions and requirements. Our technical team will conduct a detailed site survey to assess headroom, side clearance, structural conditions, and any specific operational needs before finalising the door specification.

Due to the bespoke nature of this product—including track configuration, control integration, colour options, and safety equipment—pricing is provided on application following the site survey.