The Hormann HS 5015 Acoustic H is a high-performance industrial door engineered to solve one specific problem: industrial noise pollution. By combining the rapid opening speeds of a high-speed door with the sound-blocking density of a permanent wall, it allows you to partition loud machinery without disrupting logistical flow.

Why Choose This Door?

- Significant Noise Reduction: Specialised acoustic core delivers up to 31 dB sound reduction, protecting staff from harmful noise levels.

- Optimised Efficiency: High opening speeds (up to 2.5 m/s) ensure traffic flows smoothly between production zones.

- Space-Saving Installation: "High-Lift" track system diverts the door above obstacles like crane tracks or pipework.

- Enhanced Durability: Features a wear-free belt counterbalance system, eliminating the maintenance costs of traditional spring-loaded doors.

- Description

- Application

- Specification

- Installation

- Measure

Hormann HS 5015 Acoustic High-Speed Industrial Door

Product Overview

The Hormann HS 5015 Acoustic H combines the rapid opening speeds of a high-performance industrial door with the sound-dampening properties of a permanent partition. Designed specifically for internal applications where noise levels are a critical concern, this door allows businesses to isolate loud machinery and production zones without compromising logistical efficiency.

By effectively reducing noise transfer, the HS 5015 Acoustic H helps facilities meet health and safety standards while maintaining the fast material flow required in a modern factory environment.

Key Features & Benefits

1. Advanced Acoustic Insulation

Unlike standard high-speed doors, the HS 5015 features a specialised "sandwich" profile construction designed to absorb sound. The door leaf is manufactured from robust aluminium hollow profiles, filled with a dense combination of:

- 5 mm Heavy PVC (for mass and sound deflection)

- 30 mm PU-Foam (for absorption and stability)

This heavy-duty infill acts as a barrier to high-decibel noise, creating a tangible improvement in working conditions on the "quiet" side of the door.

2. Commercial Noise Control

In commercial environments, controlling noise pollution is more than a luxury—it is a necessity. Installing the HS 5015 provides immediate benefits:

- HSE Compliance: Assists in lowering daily personal noise exposure levels for staff, protecting hearing health.

- Zone Separation: Effectively isolates loud manufacturing processes (such as stamping, printing, or grinding) from quiet assembly lines, dispatch areas, or production offices.

- Enhanced Productivity: Reducing background roar improves voice communication and concentration levels for nearby workforce.

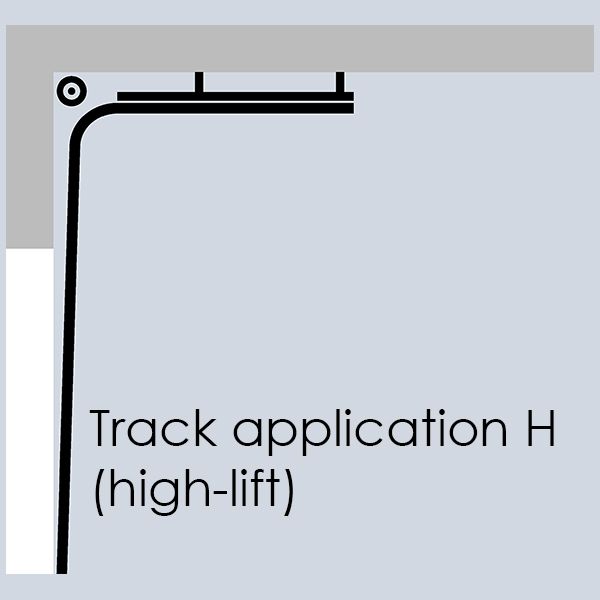

3. High-Lift Track Application (Version H)

The "H" designation stands for the versatile High-Lift track application. The galvanised tracks guide the door sections horizontally deep into the building, offering exceptional installation flexibility:

- Obstruction Clearance: The door can be diverted to fit behind or above supply lines, ventilation ducts, and crane tracks.

- Space Optimisation: Ideal for buildings with specific ceiling constraints, requiring a minimum headroom of 1000 mm.

4. Wear-Free Counterbalance Mechanism

To handle the additional weight of the acoustic panels while maintaining high opening speeds, the door utilises a reliable belt mechanism with counterweights:

- Perfect Balance: The counterweights ensure the door leaf is weight-neutral at every stage of travel, putting minimal stress on the drive unit.

- Long Service Life: This system is exceptionally low-wear and long-lasting compared to spring-tensioned alternatives, reducing maintenance costs over the door's lifetime.

Application Suitability

The HS 5015 Acoustic H is the definitive choice for:

- Automotive & Heavy Industry: Separating press shops and bodywork areas from final assembly.

- Printing & Paper: Isolating high-speed printing presses from quality control zones.

- Machine Shops: Enclosing CNC machining centres or grinding stations to prevent noise spill.

The Hormann HS 5015 Acoustic H is engineered for environments where sound attenuation is as critical as operational speed. It bridges the gap between logistical efficiency and occupational health, making it an essential asset for modern manufacturing and heavy industry.

Unlike standard PVC speed doors which offer minimal resistance to noise, the rigid composite panels of the HS 5015 create an effective acoustic barrier. This makes it the ideal solution for partitioning aggressive noise sources while maintaining high-frequency traffic flow.

Ideal Applications

Automotive & Heavy Manufacturing

In large-scale production halls, specific zones often generate dangerous noise levels. The HS 5015 is perfectly suited for:

- Press Shops: Isolating the intense vibration and impact noise of metal stamping presses from adjacent assembly lines.

- Body Shops: Containing the noise from grinding and welding robots.

- Testing Facilities: Enclosing engine test cells or "rattle and squeak" test tracks where acoustic separation is mandatory for accurate readings.

Printing & Paper Industries

High-speed printing presses run continuously and generate a constant, high-decibel drone. Installing an HS 5015 allows:

- Process Separation: Separation of the noisy printing hall from the quieter finishing and quality control (QC) areas.

- Climate Control: The insulated panels also help maintain stable humidity and temperature levels required for paper storage, preventing curling or misfeeds.

Machine Shops & CNC Centres

CNC milling and turning centres can create high-pitched, piercing frequencies. This door protects nearby staff:

- Operator Protection: Reduces the ambient noise level for programmers and supervisors working in offices adjacent to the shop floor.

- Dust Containment: The rapid opening cycle minimises the escape of fine metal dust and coolant mist into clean passageways.

Logistics & Warehousing

While primarily an acoustic door, its thermal properties make it excellent for:

- Loading Docks: separating busy, cold loading bays from warmer internal picking zones.

- Forklift Routes: The "High-Lift" track system allows the door to follow the roof line, keeping floor space clear for high-mast forklifts and racking systems.

Why Choose the HS 5015 Acoustic H for Your Facility?

1. Health & Safety Compliance

Prolonged exposure to noise above 85 dB can cause permanent hearing damage. By installing the HS 5015, you actively reduce the "noise dose" for your employees, helping your facility comply with strict HSE noise-at-work regulations.

2. Improved Communication

In a quieter environment, team members can communicate effectively without shouting. This reduces misinterpretation of instructions and lowers the risk of accidents caused by missed warnings.

3. Unhindered Productivity

Standard acoustic doors are often heavy, slow, and difficult to open. The HS 5015 opens at speeds of up to 2.5 m/s, ensuring that your acoustic barrier never becomes a bottleneck in your production line.

Technical Specification: Hormann HS 5015 Acoustic H

Dimensions & Size Range

- Max. Width: 5000 mm

- Max. Height: 5000 mm

- Min. Headroom: 1000 mm (High-Lift H Track)

Acoustic Performance

- Sound Reduction Index (Rw): Up to 31 dB (without glazing)

- Compliance: Tested in accordance with DIN EN 717-1

- Application: Suitable for separating high-noise industrial zones (e.g. press shops, grinding areas) from quiet working environments.

Curtain Construction

- Profile Type: 42 mm Aluminium Hollow Profile

- Infill Material: High-density composite core:

- 5 mm Heavy PVC (Mass layer)

- 30 mm PU-Foam (Absorption layer)

- Surface Finish: Elegant Micrograin finish on exterior

- Glazing Options: Optional acoustic-rated vision panels available (may affect total dB rating)

Performance Data

- Opening Speed: Approx. 1.5 – 2.5 m/s (Dependent on control unit)

- Closing Speed: Approx. 0.5 m/s

- Wind Load Class: Class 4 (max. 133 km/h) in accordance with EN 12424

- Thermal Efficiency: Insulated core provides thermal separation alongside acoustic benefits

Drive & Control

- Control System: Frequency Converter (FU) Control as standard (AS 500 FU E)

- Operation: Soft-Start / Soft-Stop for smooth, low-wear travel

- Counterbalance: Wear-free belt mechanism with counterweights (no springs to tension or replace)

- Cycle Life: Engineered for high-frequency industrial use

Safety Features

- Safety Light Grille: Integrated into the side elements, monitoring the door closing zone up to a height of 2500 mm. Stops the door immediately if the beam is broken.

- Emergency Opening: Manual emergency chain hoist as standard for operation during power failure.

| Track application |

Spiral track application |

Track application N (normal) |

Track application H (high-lift) |

Track application V (vertical) |

| Counterbalance | ||||

| Chain mechanism and springs | ● | ● | ||

| Belt mechanism and counter weights | ● | ● | ||

| 42 mm steel sandwich section, PU-foamed, with thermal break | ||||

| Door type | HS 7030 PU 42 | HS 5015 PU N 42 | HS 5015 PU H 42 | HS 6015 PU V 42 |

| Max. width (mm) | 6500 | 5000 | 5000 | 6500 |

| Max. height (mm) | 6500 | 6500 | 6500 | 6500 |

| Min. required headroom (mm) | 920 | 480 | 750 | LDH + 585 |

| 67 mm steel sandwich section, PU-foamed, with thermal break | ||||

| Door type | HS 5015 PU H 67 |

HS 6015 PU V 67 |

||

| Max. width (mm) | 5000 | 6500 | ||

| Max. height (mm) | 6500 | 6500 | ||

| Min. required headroom (mm) | 950 | LDH + 735 | ||

| 100 mm steel sandwich section, PU-foamed, with thermal break |

||||

| Door type | Iso Speed Cold H 100 | Iso Speed Cold V 100 | ||

| Temperature range (deviating temperatures on request) |

|

Fitting side to 0°C Opposite side -28°C |

Fitting side -28°C Opposite side -28°C |

|

| Max. width (mm) | 5000 | 5000 | ||

| Max. height (mm) | 5000 | 5000 | ||

| Min. required headroom (mm) | 750 | LDH + 585 | ||

| 42 mm aluminium hollow profile, filled with 5 mm UPVC and 30 mm PU foam |

||||

| Door type | HS 5015 Accoustic H | |||

| Max. width (mm) | 5000 | |||

| Max. height (mm) | 5000 | |||

| Min. required headroom (mm) | 1000 | |||

| ● = Standard | ◌ = Optional | LDH = clear passage height | |

Professional installation is strongly recommended for this high specification door

professional configuration for this door is required to ensure the correct specification and sizes for ordering. Please call or email with your requirements