- Description

- Application

- Specification

- Installation

- Warranty

- Measure

Seceurodoor Steel Roller Shutter – 240V Tube Motor Drive

Product Overview

Low to medium use, high quality, industrial 'Traditional' build and commercial specification roller shutter door using a single phase 240V electric tube motor for operation. This economical solution is specifically designed for low-frequency applications where simplicity, space efficiency, and cost-effectiveness are priorities.

240V Tube Motor Technology

Electric tube motor roller doors are typically specified for low usage openings with minimal daily use, as they do not have the high operational ratings required for multiple daily cycles. However, they offer several distinct advantages for the right application:

Tube Motor Benefits and Features

- Completely Hidden Installation: Motor is neatly integrated and built inside the barrel for the roller curtain, creating a clean, concealed appearance

- Space-Saving Design: No external motor housing required – ideal for installations with limited headroom or sideroom

- Minimal Visible Components: Only limit settings and cabling for power and controls are visible externally

- Standard UK Power Supply: Operates on single phase 240V – no three phase electrical installation required

- Cost-Effective Solution: Lower equipment and installation costs compared to chain drive or direct drive alternatives

- Quiet Operation: Compact tubular design produces minimal operational noise

- Simple Maintenance: Fewer external moving parts reduce long-term maintenance requirements

Operational Limitations and Considerations

240V electric tube motors cannot be used on very high openings as they do not have the required pulling force for large or heavy curtains. This motor type is specifically engineered for low-frequency use and is most suitable where door operation is intermittent rather than continuous.

Typical Applications

Ideal use would be on factory units, farm buildings, workshops, or warehouses where there may be 10 to 20 operations per day or less. Perfect applications include:

- Agricultural buildings with seasonal or periodic access requirements

- Workshop and storage units with infrequent daily operation

- Small warehouses with limited traffic flow

- Industrial units requiring secure closure overnight with minimal daytime access

- Retail back-of-house storage areas with controlled access

- Factory units with low-frequency loading bay usage

Internal Manual Override System

This roller shutter includes an internal manual override facility as standard, ensuring operational continuity during power failures or electrical faults. The system uses a winding handle with the exit for attachment located underneath the roller curtain, integrated with the motor on the same side as chosen during installation.

This backup operation method provides essential building access security and compliance with safety regulations requiring alternative means of operation.

Curtain Construction Options

This door features a strong single-skin galvanised steel profile curtain, available in multiple gauge options to suit your security and budget requirements:

- 18 gauge (1.2mm): Maximum security and strength – Price on application (POA)

- 20 gauge (0.9mm): Standard commercial specification – excellent balance of security and value

- 22 gauge (0.7mm): Economy specification for lower security requirements and budget-conscious installations

All curtain gauges are manufactured from galvanised steel as standard, providing reliable corrosion resistance and longevity across all UK weather conditions.

Colour and Finish Options

- Galvanised Steel Finish: Natural protective finish as standard

- Powder Coat: Can be powder coated to any RAL or BS colour specification

- Plastisol Colours: Durable plastisol coating options available for enhanced weathering performance

Manual Spring & Lock Option

When there is no power available for electric operation, or the shutter will not be opened very often, a manual spring and lock operation provides a practical alternative. This solution is available for shutters up to 2.8m tall, offering complete independence from electrical supply.

Technical Specifications Summary

- Motor Type: Single phase 240V electric tube motor

- Curtain Options: 18 gauge (POA), 20 gauge, or 22 gauge galvanised steel

- Application Type: Medium security office/commercial/industrial applications

- Maximum Width: Up to 7000mm (electric tube motor)

- Maximum Height: Up to 5000mm (electric tube motor)

- Manual Spring & Lock: Maximum width 6000mm, maximum height 2.8m

- Typical Daily Operations: 10-20 cycles per day

- Manual Override: Internal winding handle system (standard)

- Installation Type: Traditional build, internal or external mounting options

- Colour Options: Galvanised, powder coat (any RAL/BS), plastisol coating

Quality Assurance & Compliance

ALL Seceurodoor products are:

- CE or UKCA Marked: Full compliance with UK regulations for commercial use. Approved LPCB products also available.

- ISO 9001 & ISO 14001 Certified: Manufactured within a UK company certified to ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) standards.

- Made to Measure: Every door is manufactured to your exact specifications as standard for a perfect fit at no extra charge.

- Premium Components: Using the highest quality components and electric motor drives for the best overall package with the most reliable operation.

Why Choose the 240V Tube Motor Seceurodoor?

For UK commercial and industrial property operators requiring economical, space-efficient security with low operational frequency, the tube motor Seceurodoor represents excellent value. The concealed motor design, standard UK electrical compatibility, and flexible gauge options ensure this door suits applications from agricultural buildings to small warehouses where simplicity and cost-effectiveness are paramount.

With multiple curtain gauge options, extensive colour choices, and the option for manual spring operation, this door provides versatile solutions for a wide range of low-use commercial and industrial security requirements.

Applications & Typical Use

Ideal Applications for the 240V Tube Motor Seceurodoor

The 240V tube motor Seceurodoor is specifically designed for low-frequency applications with minimal daily operation—typically 10 to 20 operations per day or less. This cost-effective solution is the perfect fit for:

- Agricultural farm buildings and storage barns

- Workshop and trade unit access points

- Small warehouse loading bays and access gates

- Industrial unit secure overnight closures

- Retail back-of-house storage and stockrooms

- Factory maintenance and equipment storage areas

- Leisure facilities with controlled off-hours access

- Office buildings with secure service entrances

- Secure storage facilities with infrequent daily access

Practical Security on a Budget

The 240V tube motor Seceurodoor offers genuine high-quality construction and reliable security performance at an accessible price point. This makes it ideal for property owners and facility managers who need certified security infrastructure without premium investment, particularly for applications where door operation is intermittent rather than continuous.

Multiple curtain gauge options (18g, 20g, 22g) allow you to select the security level appropriate to your specific risk profile and budget constraints.

Space-Efficient Installation Benefits

The integrated tube motor design, completely concealed within the roller barrel, makes this door particularly valuable for installations with limited headroom or sideroom constraints:

- Properties with restricted architectural space above doors

- Buildings where external motor housings would compromise aesthetics

- Retrofit installations in existing structures with tight access

- Heritage or sensitive locations requiring neat, discrete appearance

- Urban commercial properties where external equipment is not practical

Cost-Effective Low-Usage Security

For properties requiring secure overnight closure but with minimal daytime traffic, the 240V tube motor configuration delivers excellent value. The economical single phase 240V motor combined with standard UK electrical supply compatibility means no costly electrical infrastructure upgrades are needed.

Typical usage scenarios include factory units opening once or twice daily, agricultural buildings accessed seasonally, or workshop facilities with controlled access outside normal working hours.

Flexibility for Different Security Needs

The availability of three curtain gauge options provides flexibility to match security investment to actual risk levels:

- 18 Gauge (Premium): Maximum security for high-value storage or sensitive operations

- 20 Gauge (Standard): Balanced security and value for most commercial applications

- 22 Gauge (Economy): Practical security for lower-risk areas or budget-limited installations

Manual Operation Backup

The integrated manual winding handle provides complete operational independence. If electrical supply is interrupted or the door is rarely opened, manual operation ensures building access is never compromised. This is particularly valuable for remote agricultural buildings, isolated units, or installations where power reliability may be a concern.

Typical Operational Profile

The 240V tube motor Seceurodoor is optimally suited for buildings with the following operational characteristics:

- 10-20 door operations per day maximum

- Intermittent rather than continuous usage pattern

- Standard UK single phase 240V electrical supply available

- Openings up to 7000mm wide and 5000mm high (electric operation)

- Indoor or covered outdoor installation preferred

- Minimal thermal insulation requirements

- Standard or enhanced security requirements (gauge-dependent)

Is This the Right Solution for Your Building?

If your building requires reliable, cost-effective security for low-frequency access with minimal electrical infrastructure requirements and space constraints, the 240V tube motor Seceurodoor represents outstanding value.

Our technical team can help you select the appropriate curtain gauge and finish options to match your security needs and budget. We can also advise whether the manual spring & lock alternative might better suit your specific application.

Contact us today for expert advice on specification, pricing, and installation options tailored to your specific low-use security requirements.

Technical Specification

Curtain Construction Options

This specific model build uses a 22-gauge galvanised steel single-skin curtain available in various colour finish options as well as the natural galvanised steel finish.

A slightly more expensive 20-gauge curtain option is also available, providing enhanced security and durability for applications requiring higher specification protection.

Traditional Build Configuration

This model is a Traditional build roller shutter door. For detailed information on Traditional build specifications and how this compares to other build types, please refer to our comprehensive guide on how to choose and order a Seceurodoor roller shutter door.

240V Tube Motor Control Systems

The electric door tube motor can be controlled by two main methods, each offering different levels of convenience and safety features:

Option 1: Internal Push Button Station (Hold-to-Run)

The most basic and standard method is an internal wall-mounted push button station with hold-to-run logic. The operator stands and holds the button firmly for the duration of the opening or closing cycle. With this configuration, no safety edge or beam systems are legally required, keeping costs to a minimum. Please note: you must be able to enter the building via another door for this method to be practical.

Option 2: Wall-Mounted Control Panel with Remote Handsets

The second option is a wall-mounted control panel with the addition of remote control handsets. This system provides significantly enhanced convenience and flexibility:

- Standard Supply: Two remote control handsets supplied as standard

- Expandable: Additional handsets available as required for multi-operator sites

- Safety Edge Detection: Built into the bottom T-rail section to stop if an obstacle is encountered during operation

- Enhanced Safety: If the door is adjacent to any public pathway or road, we recommend additional safety with infra-red beams to further enhance protection

- Operational Flexibility: Operate from distance, ideal for busy access points or where multiple operators need access

Colour and Finish Options

This roller door is available with the curtain pre-finished in multiple coating options to suit your building's aesthetic and environmental requirements:

Powder Coat Finish

The curtain can be pre-finished in a powder coat which provides the same colour on each side of the slat, ensuring consistent appearance and enhanced durability.

Plastisol Coated External Finish

Available in a plastisol coated external finish, which has a standard off-white internal paint finish, providing excellent weathering performance and durability in exposed locations.

Natural Galvanised Steel

As a totally standard option, and used by many customers depending on the roller door location, you can have the steel curtain in its natural galvanised steel finish. This provides excellent corrosion resistance and a clean industrial appearance.

Custom Colours and Mix-and-Match Options

We can offer the door in special colours beyond those shown in our online shop options. You can also mix and match the guides, hood cover, and curtain finishes if required to create a bespoke appearance matching your building's colour scheme. Please email or call for details and pricing on custom colour specifications.

Material Specifications Summary

| Curtain Material (Standard): | 22-gauge galvanised steel, single-skin construction |

| Curtain Material (Optional): | 20-gauge galvanised steel, single-skin construction |

| Lath Profile: | 75mm scrolled lath design |

| Guide Rails: | Galvanised steel |

| End Plates: | Galvanised steel |

| Motor Type: | Single phase GfA 240V electric tube motor |

| Power Supply: | Single phase 240V (standard UK supply) |

| Motor Configuration: | Integrated within roller barrel (completely concealed) |

| Intended Usage: | Low-use applications (10-20 operations per day) |

| Standard Control: | Hold-to-run push button station |

| Optional Control: | Remote control system (2 handsets standard, expandable) |

| Safety Features: | Safety edge detection (remote control option), infra-red beams (optional, recommended for public access) |

| Manual Override: | Internal winding handle system (standard) |

| Maximum Width: | Up to 6000 mm |

| Maximum Height: | Up to 4800 mm |

| Build Type: | Traditional build (internal or external mounting) |

| Colour Options: | Natural galvanised, powder coat, plastisol coated, custom RAL/BS colours available |

| Customisation: | Mix-and-match guides, hood cover, and curtain colours available |

| Installation Method: | Traditional build configuration |

Control System Comparison

| Feature | Hold-to-Run Push Button | Remote Control System |

| Installation Cost: | Minimum | Moderate |

| Safety Edge Detection: | Not required | Built-in standard |

| Remote Operation: | Not available | 2 handsets standard, expandable |

| Operator Convenience: | Manual hold required | Single button press (momentary) |

| Multi-Operator Support: | Limited | Multiple handsets available |

| Recommended For: | Low-traffic, single operator sites | Active facilities, multiple users, public areas |

Quality Assurance & Compliance

ALL Seceurodoor roller doors are:

- CE or UKCA Marked: Full compliance with UK regulations for commercial use.

- ISO 9001 & ISO 14001 Certified: Manufactured within a UK company certified to ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) standards.

- Made to Measure: Every door is manufactured to your exact specifications as standard for a perfect fit at no extra charge.

- Premium Components: Using the highest quality components and electric motor drives for reliable, long-term performance.

Full installation details are provided with each door and the SeceuroDoor roller shutter doors are specifically designed to be fitter friendly.

SeceuroDoor Product Warranty

All SeceuroDoor products, including the industrial motor, are guaranteed against defects of material or workmanship by SWS UK, subject to correct installation, maintenance and operation, for a period of 1 year from the date of purchase. This comprehensive warranty provides peace of mind and protection for your investment in premium industrial door solutions.

Extended Warranty for GfA Motors

An exclusive extended 2-year warranty is available on GfA industrial motors when you register each drive using the GfA bluetooth dongle. Registration is straightforward and provides additional benefits including viewing and tracking all registered GfA assets in one place, monitoring ongoing usage patterns, keeping track of drive settings over time, accessing a comprehensive library of fault codes, and synching your service records.

Warranty Coverage

SWS UK will replace or repair any components of our products where the manufacturing process has resulted in a defect occurring during the relevant warranty period, subject to the exceptions and conditions detailed below. For all replacement electrical parts, the warranty period is 12 months or the remainder of the original warranty period, whichever is the longest.

Warranty Limitations and Exclusions

The SeceuroDoor warranty does not cover the following circumstances:

Visual Quality Standards

- Marks, distortion, stains, blemishes, indentations or scuffs which are not observable from at least 3 metres away in natural light (not direct sunlight)

- Minor variations in finish associated with the manufacturing process

- Impact damage or scratches, dents, scuffs or other minor abrasions occurring post-installation

Installation and Maintenance Issues

- Incorrect installation of the product, not following SWS UK's installation instructions

- Incorrect operation of the product or lack of proper care and maintenance in accordance with SWS UK's Operating & Maintenance Manual

- Any modifications made to the product by anyone other than SWS UK

- Use or attempted use of non-SWS UK spare parts

- Repairs or attempted repairs undertaken by any person other than someone specifically authorised by SWS UK

- Any attempt to reduce operating clearances by means of infills or draughtproofing

Normal Wear and Environmental Factors

- Normal wear and tear from regular usage

- Accidental or malicious damage from third parties

- External influences such as extreme or abnormal weather conditions, fire, water, salts, chemicals and bird droppings

- Any fault or surge in the customer's electricity supply

- Any failure of masonry or other structures onto which the product has been fixed

Coastal and High-Corrosion Environments

- Rust or corrosion caused by exposure to saltwater or salty air for products installed within 500 metres of the sea or a large body of saltwater

- For products installed within 2 miles of the sea, the exterior finish of the product is guaranteed for a limited period of 2 years only (regular weekly cleaning with warm water and mild detergent is essential)

Consumables and Consequential Costs

- Consumable items such as fuses, light bulbs or batteries

- Indirect, special or consequential loss or damage howsoever caused, including remedial work costs, call-out fees, tool or plant hire and transport costs

Important Warranty Conditions

The SeceuroDoor warranty covers parts only and does not cover labour costs or consequential costs. This includes but is not limited to call-out fees, transport costs and costs for remedial work for removing and/or re-installing faulty parts. All warranty claims must be reported promptly to allow for timely assessment and resolution.

Product Care Requirements

To maintain warranty validity and prolong the life of your SeceuroDoor product, correct operation and care in accordance with the official Operating & Maintenance Manual is essential. Regular maintenance includes wiping with a damp cloth and mild detergent to remove excessive dirt and grime, ensuring the floor is kept smooth, level and clear of dirt and debris which can damage the rubber seal, and conducting visual inspections to identify any issues before they develop into major problems.

Coastal Installation Requirements

Products installed in coastal environments or high-corrosion areas require enhanced maintenance protocols. Regular cleaning of products in locations within 2 miles of the sea is especially important. Doors should be cleaned thoroughly weekly using warm water and mild detergent with a soft cloth or sponge, allowed to dry naturally. Never use strong detergent, abrasive, caustic or solvent-based cleaners as these will void the warranty.

Visual Quality Assessment Standards

We recommend performing a visual quality check on installation. Carry out the quality check in natural daylight, not direct sunlight. Stand at a distance of 3 metres from the product to view the overall appearance. The product is acceptable if, taking into account the manufacturing process, none of the following is readily visible on the face of the product: marks or distortions associated with the manufacturing process, minor indentations, marks or scuffs on the surface, or paint or stain blemishes.

Making a Warranty Claim

For warranty claims or technical support, please contact Samson Doors on 01933 448 850 or email enquiries@samsondoors.co.uk. Please have your order details, installation date, and a clear description of the issue available. Our technical team will assess the claim and arrange appropriate resolution in accordance with the warranty terms.

Protecting Your Investment

Regular professional servicing and maintenance by qualified engineers will help ensure optimal performance and longevity of your SeceuroDoor product. Samson Doors offers comprehensive maintenance contracts and emergency repair services across the UK to keep your industrial doors operating reliably year after year.

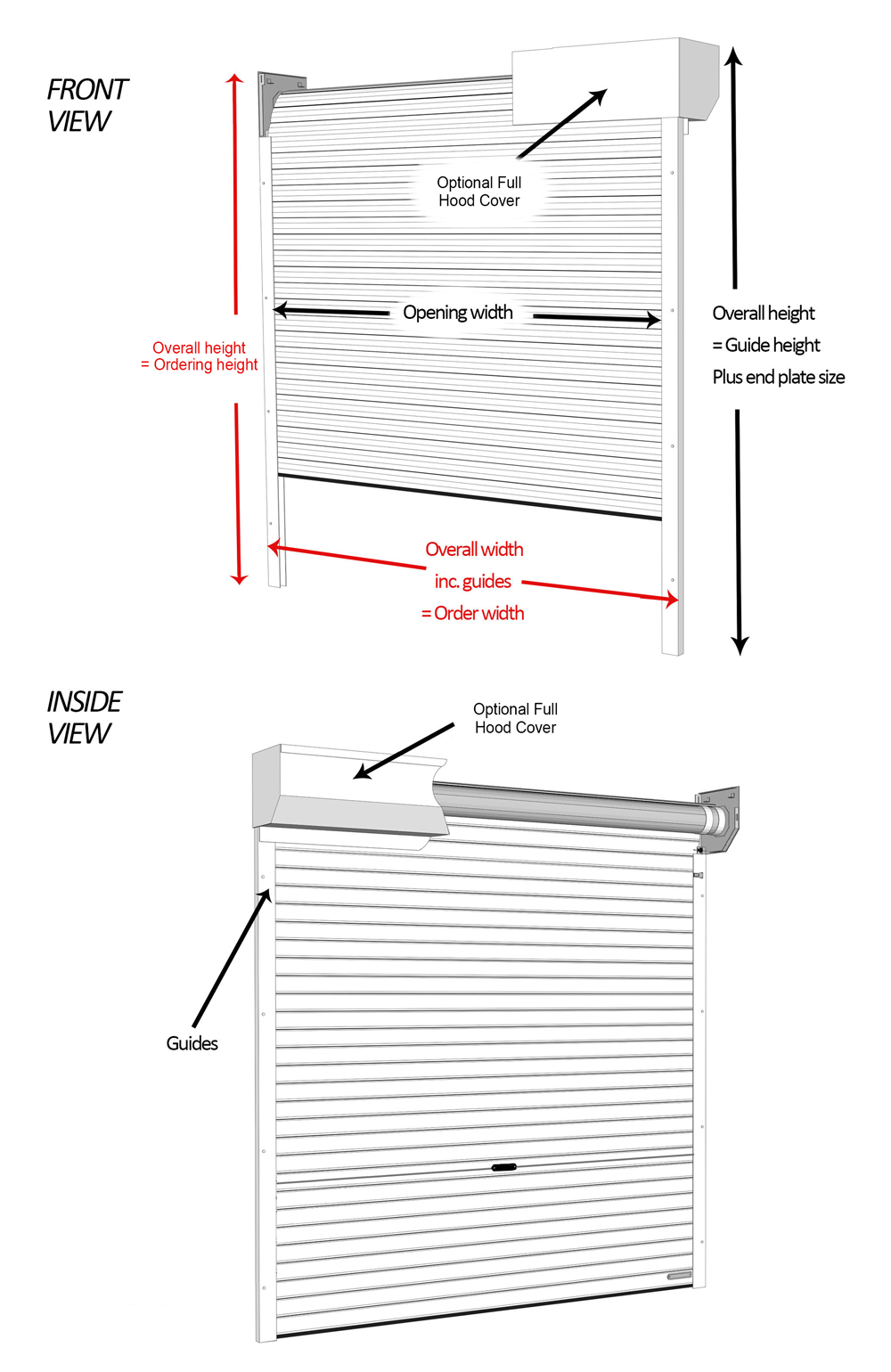

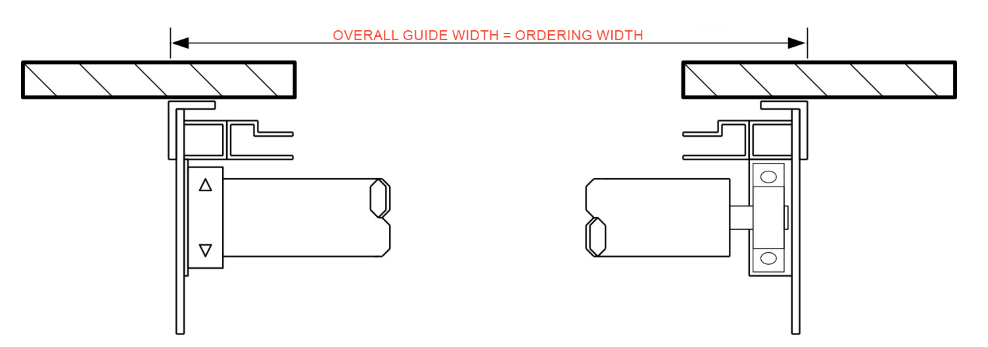

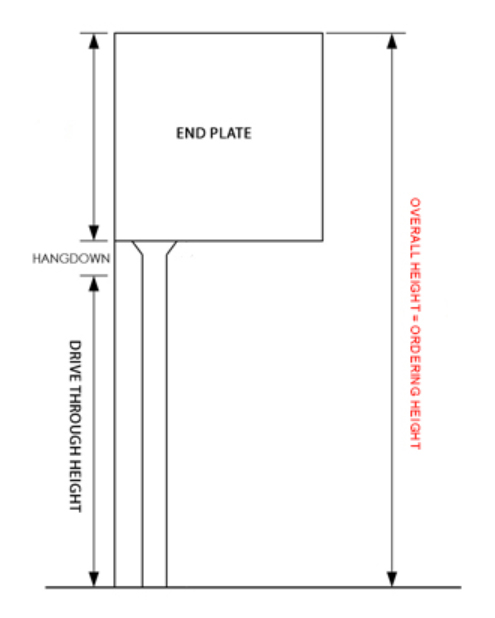

Traditional Build Tube Motor Driven Arrangement and Ordering Dimensions

Continential Build Tube Motor Driven Arrangement and Ordering Dimensions