- Description

- Specification

- Installation

- Warranty

The SeceuroGuard 1000 Medium Window Security Grille is a high quality collapsible steel security grille specifically configured for medium-sized window openings in both domestic and commercial properties. Available in made to measure sizes up to 2400mm wide and 2100mm high, this version of the SeceuroGuard 1000 provides effective security for standard and larger window openings whilst maintaining all the quality and functionality of the full SeceuroGuard range.

Key Features:

- Strong security barrier and deterrent for medium windows

- Galvanised for corrosion resistance and powder coated

- Fully retractable system for easy access and cleaning

- Excellent through-vision and ventilation when locked

- Multi-point locking (2 or 4 point) from a single key

- Smooth running carrier system ensures quick and easy operation

- Configured for medium window openings up to 2400mm x 2100mm

- Available in single or double sash arrangements

- Custom built for almost any medium-sized window opening

- All the quality of SeceuroGuard 1000 in a medium window solution

SeceuroGuard 1000 Retractable Security Grille - Technical Specification

Product Overview

The SeceuroGuard 1000 is a made-to-measure retractable security grille designed for internal medium to high security applications in domestic, commercial, and retail environments. Manufactured from pre-galvanised steel with a smooth, durable powder-coated finish.

Size Capabilities

• Maximum Width: 6000mm (single sash up to 3000mm; unlimited width possible with multiple sashes)

• Maximum Height: 3500mm

• Minimum Width: No minimum restriction

• Minimum Height: 500mm

Construction & Materials

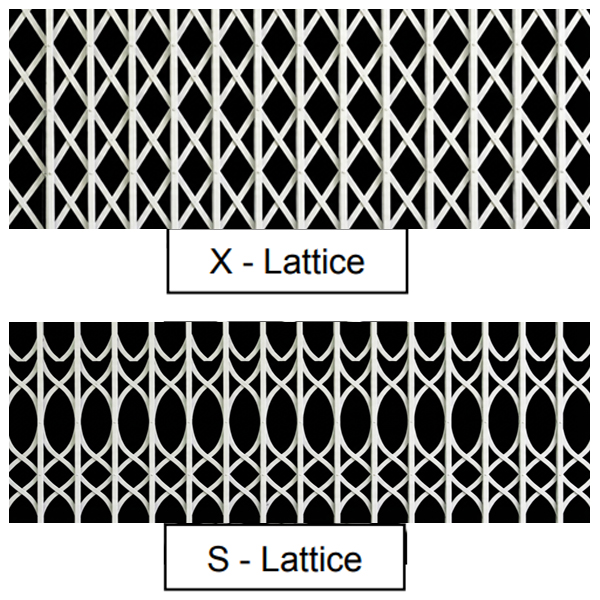

• Lattice Design: High-grade pre-galvanised steel in classic 'X' lattice (standard) or modern 'S' lattice (optional, same price)

• Lattice Weight: 19kg/m² nominal

• Assembly System: Steel riveted lattice assembly for exceptional strength and durability

• Bearings: Top hung on nylon-coated steel bearings for smooth, quiet operation

• Frame: All galvanised steel construction

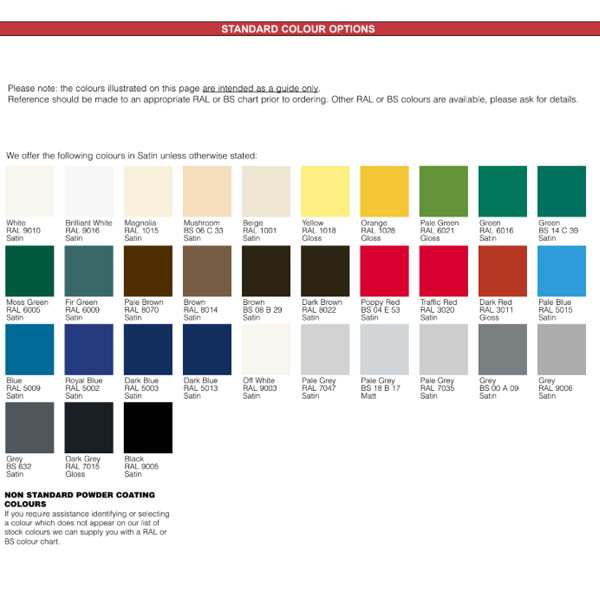

• Finish: Powder-coated in a choice of 27 standard colours (custom RAL colours available on request)

Locking & Security

• Locking System: Multi-point locking (2-point or 4-point) operated from a single key

Installation Options

• Mounting: Face-fixed or reveal-fixed to suit opening requirements

• Configuration: Single sash or bi-parting double sash arrangements

• Track Options: Standard fixed bottom track or optional fold-up/removable bottom track for clear walkthrough

• Hinge Aside: Optional hinge-aside configuration for maximum accessibility

Operation & Features

• Operation: Manual slide operation with smooth-running carrier system

• Retraction: Fully retractable—stacks compactly to sides when open

• Through-Vision: Excellent visibility and airflow even when locked

• Handling: Single sashes up to 2000mm wide manufactured in one piece; larger sections assembled on-site for safe handling

• Track Arrangement: Gates wider than 4000mm supplied with top track in two sections (centre split)

Standard Colours

Brilliant White (RAL 9016), Black (RAL 9005), Anthracite Grey (RAL 7016), Brown (RAL 8014), and 23 additional standard powder-coated colours. Non-standard colours available—please enquire.

Additional Options

• Fixed sash panels (where access not required)

• Locking posts at both ends for maximum operational flexibility

• Custom colour matching service available

• Split sash arrangements for extra-wide openings

Quality & Compliance

• Manufacturing: UK-manufactured by SWS UK to ISO 9001:2015 standards

• Corrosion Protection: Pre-galvanised steel construction with powder-coated finish

• Warranty: 2-year parts warranty (see Warranty tab for full details)

Important Notes

• Sashes manufactured in single pieces up to 2000mm wide ensure structural integrity

• Larger gates supplied in sections with bolts and fixing plates for on-site assembly

• Top tracks for gates over 4000mm wide supplied in two pieces with centre split

• Where split sashes meet, pickets are joined using supplied bolts and fixing plates

Related Products

For enhanced security requiring insurance approval, consider upgrading to the SeceuroGuard 1001, independently tested and certified to Loss Prevention Standard LPS 1175 Security Rating 1.

Smaller grilles are simple to handle and install generally and it is only when the sizes and weights exceed a single person handling that you require 2 or more people to assist and manouvre the components into place.

For optimal performance and warranty compliance, we strongly recommend professional installation by qualified security grille installers or tradesmen used to installing doors, windows and other products requiring associated skills. SeceuroGuard grilles require precise measurement, secure substrate fixing, and correct assembly—particularly for the SR1 rated SeceuroGuard 1001 model where LPS 1175 certification validity depends on installation meeting LPCB requirements.

Installation Methods

The SeceuroGuard range offers three primary installation configurations to suit different architectural requirements:

- Face-Fixed with Bottom Track - Complete framework mounted to wall surface with floor-mounted bottom track

- Face-Fixed to Aperture - Framework fitted around opening perimeter with additional support profiles

- Reveal-Fixed Within Aperture - Compact installation within window or door recess

Ordering Dimensions - Critical Information

SeceuroGuard grilles are always ordered using Overall Width and Overall

Pre-Installation Requirements

Essential Tools & Equipment:

- Spirit level and measuring tape

- Hammer drill with appropriate masonry bits (for brick/block) or metal drill bits (for steel frames)

- Socket set and spanners

- Screwdriver set (Phillips and flathead)

- Safety glasses and dust mask

- Stepladder or access platform

Secure fixing requires:

- Brick/Block Walls: Minimum 100mm embedment depth with resin anchors or expansion bolts

- Steel Frames: Through-bolting with appropriate grade fixings

- Timber Frames: Coach screws to structural timber (not suitable for all applications)

- Weak Substrates: May require reinforcement—consult a structural engineer

Installation Process Overview

- Verify opening dimensions match order specifications

- Check substrate condition and load-bearing capacity

- Ensure adequate clearance for sash operation and bunch width (approximately 15% of overall width)

- Clear the work area and protect flooring/surfaces

- Unpack all components and verify against delivery note

- Pre-assemble track sections if supplied in multiple pieces (widths over 4000mm)

- Check all fixings, brackets, and components are present

- Position top track using temporary supports

- Use spirit level to ensure perfect horizontal alignment—critical for smooth operation

- Mark all fixing positions through pre-drilled holes in framework

- For face-fixed installations, ensure fixing frame is plumb and square

- Drill pilot holes to correct depth for substrate type

- Install fixings progressively, checking alignment after each fixing

- Torque fixings to manufacturer's specifications—avoid over-tightening

- Ensure minimum fixing centres are maintained (typically 400-600mm)

- Attach sash carrier wheels to top track

- Guide lattice sash into track system

- For larger installations, sections may require on-site joining with provided fixings

- Install lock posts and slam posts according to configuration

- Adjust multi-point locking to ensure smooth engagement

- Test lock operation through full cycle

- Check sash slides smoothly across full width

- Adjust carrier wheels if binding or resistance occurs

- Verify locking engagement is secure

- Test bottom track (if folding option specified)

Installation Considerations

-

For SeceuroGuard 1001 SR1 Rated Installations:

- Must comply with LPS 1175 installation requirements

- All fixings must meet specified security standards

- Installation certificate may be required for insurance purposes

- Substrate must provide adequate resistance—certification is void if installation is compromised

Hinge-Aside & Folding Track Options:

Common Installation Challenges:

-

Out-of-Square Openings: May require packing or shimming—check diagonals before fixing

- Uneven Floors: Particularly affects bottom track alignment—may require floor preparation

- Restricted Access: Consider installation sequence for narrow doorways or difficult access

- Overlapping Windows/Doors: Plan sash stacking location to avoid operational conflicts

Post-Installation

Remove all protective coverings and packaging

Technical Support & Downloads

For detailed step-by-step installation instructions with comprehensive diagrams, download our Samson SeceuroGuard Fitting Guide PDF

Need Installation Support?

Our technical team can provide guidance for complex installations:

- Call: 01933 448 850

SeceuroGuard retractable security grilles are backed by a comprehensive parts-only warranty from Samson Doors and SWS UK covering general product components including fixing frame, sashes, tracks, lattice, powder-coated finish, and locking mechanisms for a period of 2 years from the date of purchase.

What the Warranty Covers

SWS UK will repair or replace any part found to have a manufacturing defect during the warranty period. This includes:

- Defects in materials or workmanship affecting the operation of the retractable security grille

- Failure of the fixing frame, sashes, tracks, or lattice due to manufacturing fault

- Defective powder-coated finish (within the first 2 years from purchase date)

Faulty locking mechanisms or key operation

What the Warranty Does Not Cover

This warranty does not cover damage or faults caused by:

- Incorrect installation or failure to follow SWS UK fitting instructions

- Poor or improper maintenance or lack of regular servicing

- Incorrect use or unauthorized modifications to the grille

- Normal wear and tear, accidental damage, or malicious damage

- Labour costs, call-out fees, transport, or other consequential costs

- Cosmetic marks or blemishes not visible from 3 metres in natural light

- Exposure to corrosive environments including saltwater or salty air for products installed within 500 metres of the coast

- Rust or corrosion caused by failure to maintain the product according to SWS UK guidelines

- Damage caused by environmental factors including extreme weather, flooding, fire, or impact

- Misuse or negligence by the end user or third parties

- Products not purchased through authorized SWS UK distributors

Warranty Conditions

To maintain the validity of this warranty:

- The SeceuroGuard grille must be installed by a competent installer/person in accordance with SWS UK fitting instructions

- The product must be used for its intended purpose only (domestic or commercial security applications as specified)

- Regular maintenance must be carried out as per the operating and maintenance instructions provided

- Any warranty claim must be accompanied by proof of purchase showing the date of purchase

- Products must be purchased through authorized SWS UK distributors

Making a Warranty Claim

If you believe your SeceuroGuard grille has a manufacturing defect covered by this warranty, contact Samson Doors with your product details, proof of purchase, date of installation, and a clear description of the fault. We may request photographs or arrange an inspection to assess the claim. If the claim is valid, we will arrange repair or replacement of the defective part(s) as appropriate.

Exclusions and Limitations

-

This warranty is non-transferable and applies only to the original purchaser

- SWS UK reserves the right to repair or replace defective parts at its discretion

- Repaired or replaced parts carry a warranty for the remainder of the original warranty period or 12 months, whichever is longer

- This warranty does not affect your statutory rights under UK consumer protection legislation

- SWS UK will not be liable for any consequential loss, damage, or expenses arising from product failure.